Wire EDM for Production Machining of Larger Parts

The MV2400-ST wire EDM from MC Machinery can perform submerged cutting up to 16.5 in deep, with an annealing length over 21 in to thread the maximum workpiece height for a broken wire recovery at the start point and through the gap if needed.

Posted: January 6, 2019

In Booth 2613, MC Machinery Systems, Inc. (Elk Grove Village, IL) will showcase their MV2400-ST wire EDM that is specifically designed for larger-part production, capable of performing submerged cutting up to 16.5 in deep. With an annealing length of over 21 in, this system can thread the maximum workpiece height both at the start point and through the gap if needed for a broken wire recovery. It also features the new Mitsubishi M800 series control with a 19 in touchscreen for easier user interface than previous models. The M800 series control uses rotational and tilting functionality while showing job monitoring and important information in a single view. The new navigation interface provides smooth and easy job operation time for all operator expertise levels, allowing production jobs to be completed quickly and accurately.

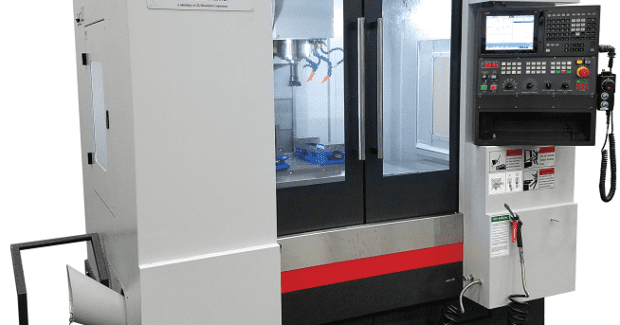

Also on display will be the MCV-1000 machining center that performs well in a wide variety of applications, including but not limited to fixtures, mold bases and secondary operations. This is a great general purpose machining center that features a 12,000 rpm spindle standard and BIG Plus CAT 40 tooling.

MC Machinery Systems, Inc., 85 Northwest Point Boulevard, Elk Grove Village, IL 60007, 630-616-5920, www.mcmachinery.com.