When the Highest Accuracy, Precision, Versatility and Control is Required

Are you bidding on jobs that involve welding the smallest of parts together without causing any damage to them? Or others that require consistent, repeatable, high quality welding of complicated joints and dissimilar materials in difficult-to-reach areas, with minimal part distortion? If so, take a closer look at some of these latest advances in laser welding.

Posted: January 19, 2019

Laser Welding Cell Forgives Imperfections

Getting started with laser welding is now easier than ever before thanks to tolerant laser welding with FusionLine technology from TRUMPF that allows for the welding of components with gaps for even simpler operation.

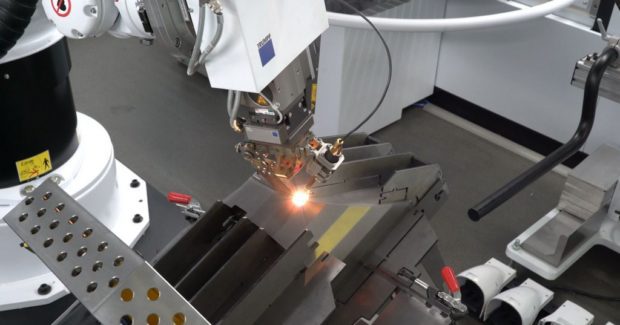

Robotic Laser Welding and Cutting Meets Demands for High Accuracy

Pre-engineered with offline programming capabilities and tools for automatic TCP calibration, work objects and positioner base frames that match various part sizes, geometries and production volumes, the IRB 2400 robot from ABB Robotics laser welds and laser cuts using world-class motion control and path performance.

A New Approach to Fiber Laser Welding

CleanWeld technology from Coherent delivers up to 80 percent spatter reduction with minimal cracking and porosity in diverse applications, including zero-gap welding of galvanized steel, automobile powertrain component welding, and aluminum and copper welding for electric car batteries.

3D Simulation and Offline Programming for Laser Welding Systems

FASTSUITE Edition 2 software from CENIT creates virtual cells for TRUMPF, Amada and other automated laser welding systems for faster creation of fixtures for prototypes, shorter cycle times for production parts and less overall programming time.

Fiber Laser Windows Reduce Focus Shift and Beam Deterioration

Ideally suited as debris shields for laser welding and cutting, Sapphire Fiber Cover Glass Windows from Laser Research Optics can withstand steel splatter, flash, and debris better than fused silica.