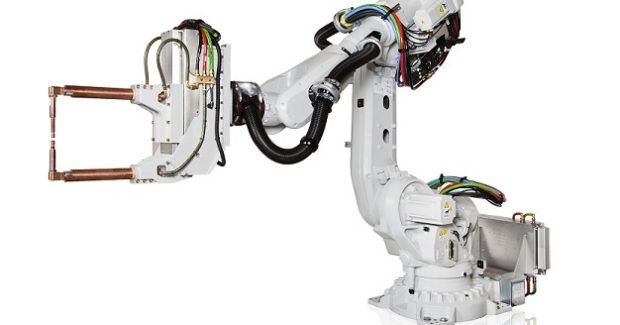

Robot Dressed for Spot Welding

The fully integrated Spot Welding Function Package on the IRB 6700 robot from ABB Robotics features an electric servo gun with parallel arm movements managed by an IRC5 robot controller to guarantee process quality in a wide range of spot weld applications.

Posted: January 4, 2019

The seventh-generation IRB 6700 robot from ABB Robotics (Auburn Hills, MI) is available with LeanID, a dressing package that integrates the most exposed parts of the dress pack into the robot for easier programming and simulation with predictable cable movements, a more compact footprint and expanded cable life due to less wear and tear. The IRB 6700 is the highest performance robot in the 150 kg to 300 kg payload class. It reaches 2.6 m to 3.2 m with enhanced speed and accuracy in floor-mounted or inverted versions. Its fully integrated Spot Welding Function Package features an electric servo gun with parallel arm movements managed by the IRC5 robot controller. Electrode Tip Dressers are available for a wide range of both horizontal and vertical dressings. The parallel arm movement enhances the rigidity of the arms to guarantee process quality in a wide range of welding solutions that meet a variety of spot weld applications.

The IRB 6700 can withstand the harshest working environments and is available with the ultimate Foundry Plus 2 protection system. This robot reduces power consumption by 15 percent, optimizes maintenance by doubling the time between service intervals versus comparable robot models, and lowers the total cost of ownership by 20 percent.

ABB Robotics, 1250 Brown Road, Auburn Hills, MI 48326, 248-391-9000, www.new.abb.com/products/robotics.