Real-Time ERP: Moving Toward the Single Version of the Truth

Browser-based ERP systems are now emerging with integrated MES and CRM applications written in native code that utilize the same logic and run on a single database to achieve a real-time manufacturing environment that better utilizes shop floor data, improves operational efficiency and maximizes profitability for small to mid-sized shops.

Posted: January 18, 2019

Over the last two decades, ERP has advanced significantly in delivering varying levels of automation to manufacturers. In the years ahead, it will accelerate further to the next paradigm shift in cloud, mobile and IoT – which includes anything from sensors and machine learning to 3D printing and wearable devices, all in a connected environment. For small and medium-size metal manufacturers and job shops (SMMs), many of these technologies simply do not make sense for their current business in terms of affordability and functionality – with one exception: In the next five to ten years, many SMMs will move toward cloud ERP as its price/performance and security become more realistic for their budgets and business models. Why? Because none of these other advanced technologies of the future inherently create value . . . their power is ultimately generated from the ERP system and the level of outcomes delivered through a totally integrated manufacturing environment of real-time processing throughout the operations.

The key challenge facing most SMMs is that they opted early on for an entry-level ERP system, hoping it would improve their ability to deliver quality products while managing inventory levels without any disruption to their business. As applications evolved, they eventually found themselves operating a mixture of small ERP systems with best-of-breed MES, CRM and other systems, while still maintaining spreadsheets for many critical enterprise processes – an environment that rarely includes a well-standardized integration interface. Instead, these shops rely on customized interfaces or add-on modules to make all of these systems connect. This is costly to maintain (considering most of them have small and limited IT resources and budgets), and also limits the enterprise-wide visibility and real-time functionality they need to compete for customers who demand more, make more changes and include contingent liability in contracts that require specific service levels and quality, faster delivery and even assurances that their suppliers’ operations are automated.

These formidable market forces demand a smart manufacturing environment that unites Big Data, MES and CRM to form a fully integrative, collaborative real-time manufacturing plant. To do this, SMMs must shift from a customized, in-house software environment to a more standardized and integrated ERP system that will deliver the real-time data critical to reaching the ultimate goal so frequently referred to as “the single version of the truth” in their operations. True real-time capability means a company’s system updates information throughout the enterprise instantaneously. It sounds simple to achieve since most effective ERP systems have this capability, but most shop floors cannot do this with their current system because it lacks integration capabilities.

For example, scheduling and shop floor reporting are two areas where many businesses use third-party software. A third-party scheduling system may enable the user to adjust work center queues, view capacity and the latest schedule data from the host system download, but changes from the front office – rush orders, customer expediting and sales order cancellations – may not be communicated to the scheduler until the next batch download, leaving the scheduling staff to operate with an incomplete schedule. While changes in the scheduling system may be made in real-time within that module, the input cannot be made in real-time from other modules – a disconnect from the rest of the system that is exacerbated when schedule changes are pushed out in batch mode to a third-party shop floor labor data collection system where the work center queues are now in a second-order disconnect from front office order changes.

A basic ERP system also cannot provide accurate visibility into real-time shop floor conditions and their impact on customer deliverables. And without real-time feedback from the shop floor, the organization cannot see what capacity actually is throughout the day, so new order delivery estimates are hopelessly inaccurate. To make matters worse, many companies try to work around these limitations by creating multiple spreadsheets that carry duplicated and disconnected data, causing an extraordinary effort to answer a simple question like “do we really have the material to make this job?”

Integrating ERP and MES is a crucial part of achieving real-time manufacturing, particularly since MES acts as a bridge between ERP software and machine data, and as an eventual launching point for integrating factories into IoT platforms. For example, a key ERP/MES integration is with nesting software that provides a valuable insight into material utilization and enables a shop to get more parts and profit out of every sheet while reducing waste. Integration can easily be achieved here because many modern ERP systems offer a nesting interface plug-in that tightly links the shop floor cutting process.

For most SMMs, opting for a third-party CRM seems to suffice since they believe all they need is a system to provide information on quotes, when it’s due, what was won, and simple contact management. Yet frequently, the plant lacks integration with CRM and the ERP/MES, thus missing out on improving their capability to find new customers and, most importantly, retain existing ones through delivery of an exceptional customer experience. This requires complete visibility into a customer with real-time insight into order history, delivery, job profitability, payment terms or any customer data point that affects operations. So the focus should not be on adding more third-party software to a legacy system to fill out the functional holes. Instead, implement a modular-designed and browser-based ERP system that delivers full functionality for the factory floor, as well as CRM and Business Intelligence dashboards and web portals that extend business data to suppliers and/or customers.

What is the payback for a fully integrated ERP system? Timelines for ROI can vary widely and inconsistently, from several months up to 36 months, due to any disruption in business during ERP implementation. It’s best to measure the intangible benefits, such as: reduced level of inventory, which can typically average from 20 percent to 30 percent and more; improved production and quality efficiency, which minimizes shortages, waste and avoids contract penalties; lower labor costs through less overtime and improved staff allocation; reduced material costs through better procurement processes; higher revenue through better customer service; and maximized profitability through enterprise-wide visibility, detailed business-wide reports, job costing and other business intelligence analytics.

Many SMMs know that the biggest challenges to integrating their operations is the age of their systems, the architecture, and the levels of customizations of new applications they have added to those systems. Indeed, in a perfect plant environment the ERP, MES and CRM programs would be written into the same system, with one database as a single platform to deliver a seamless bi-directional flow of data from MES into ERP: data such as downtime and production reporting would update the finite scheduling, capacity planning, and CRM in real-time, rather than several hours through batch transfers. But because most shops have disparate systems, particularly MES and ERP from different vendors, they often manually enter data from one system into another in order for both to communicate with each other – which frequently leads to communication bottlenecks and poor insight into shop floor operations.

The most challenging part of integrating disparate systems and adding on new technology is the cumbersome and time-consuming process of data mapping a huge quantity of data, different data structures, schemas, semantics, query languages and APIs. In some cases, complex integrations can take several months to a year to complete and can definitely be disruptive to a business. For most SMMs, this can mean major losses or even a hit on their viability. Today’s business pressures have led many SMMs to realize that purchasing separate software applications and systems for manufacturing, accounting, MES and CRM is too difficult, costly and resource-intensive to integrate, let alone work effectively. That’s not to say it doesn’t make sense to buy best-of-breed, just that deep integration is most likely to be achieved through an integrative ERP and MES system that offers standardized APIs.

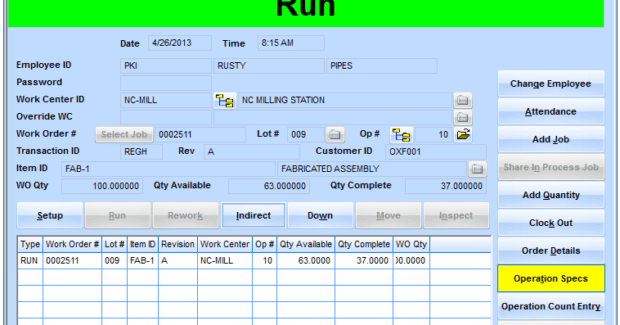

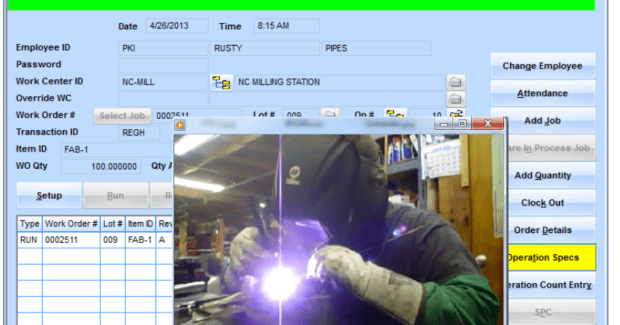

The good news is there are browser-based ERP systems with integrated MES and CRM applications written in native code, utilizing the same logic and running on a single database. Some of these also are specifically tailored for the business models of SMMs. By implementing these new systems, SMMs can achieve a real-time manufacturing environment that offers a holistic view of their business processes and production, better utilizes shop floor data to deliver that “single version of the truth” in their operations, improves operational efficiency and ultimately maximizes their profitability.