Less Wait, More Do: Why MQL is Right for You

Clean floors. Clean parts. Healthier employees. Longer tool life. More machine up-time. Better profitability. These are only a few of the reasons why to look at MQL. There’s more.

Posted: January 2, 2019

Why MQL? Minimum quantity lubrication (MQL) is just what the name implies: A means of reducing the heat generated when cutting metal that uses a very small (minimum) amount of a fluid (more specifically, a lubricant) to reduce the friction between the cutting tool and the workpiece. The exact amount for “minimum” varies depending on who you ask: The German DIN specification puts it up to 50 mL/h of lubricant (1.7 oz/h) and, in exceptional cases, up to 150 mL/h (5 oz/h). Other studies cap it at 500 mL/h (17 oz/h). The amount is somewhat subjective and depends greatly on the materials, processes, and the tools used in the specific application. Some materials have more natural lubricity than others, some processes are better able to get the fluid to the right place, and bigger tools need more lubricant than smaller ones. But as a general rule of thumb, 5 mL/h to 80 mL/h (0.2 oz/h to 2.5 oz/h) on tools less than 40 mm (1.57 in) diameter seems to keep the chips dry and gives good results. No matter where you fall in this range, it is much less than the 30,000 mL/h to 60,000 mL/h (8 gal/h to 16 gal/h) typically used with flood coolants!

WHERE IS MQL PRACTICAL?

MQL is normally the best choice for application in:

- Open machines. In these machines, flood cooling is just so plain messy that it is often not done at all. Instead, the trusty squirt bottle is used or cuts are made dry. On saws or other systems where a flood system is used, the coolant ends up running down (and through, in the case of pipes or tubes) the workpiece and all over the floor. In most of these cases, an MQL system will increase the tool life without any mess.

- Machines that are used intermittently. For the machine that sits unused for periods of time, MQL eliminates emulsions that go rancid and can end up acting as a bacteriological cesspool, complete with foul odors and related health hazards. With MQL, the lubricant is clean and stays that way until ready to use.

- Micromachining. In micromachining, most conventional processes, such as turning, milling, and drilling, can benefit from MQL. Successful micro-drilling has been reported for holes with a 10:1 depth-to-diameter ratio. MQL can significantly reduce built-up edges, burr size and cutting force, thus improving tool life. Depending on which cutting fluid is used and how it is applied, research shows that MQL can perform at least as well as flood cooling and, in many cases, extends the tool life three to ten times. As of this writing, there is not any published paper where inferior results were found using MQL over dry or flood cooling.

- High speed machining. Several studies show that MQL works better than dry machining or flood cooling in high speed machining. The dynamics are not fully understood, but the basics show that MQL output is better able to penetrate the air barrier around the tool and the tool-workpiece interface than flood coolants for better lubricity than either dry or flooding and, therefore, does a better job.

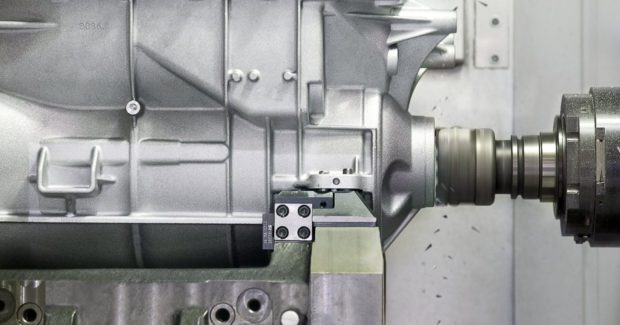

- General machining. MQL works well in many general machining operations. For example, Ford Motor Company uses it as their standard machining method for aluminum transmission prismatics, aluminum engine heads, aluminum and gray iron engine blocks, and cast and forged crankshafts oil/cross holes and balancers.

COMPETITIVE ADVANTAGES

MQL works best in cutting applications such as sawing, milling, turning, and drilling. It is not as effective in abrasive operations such as grinding, honing, and lapping, where the fluids are needed to flush away the resulting swarf to avoid gumming. Using less fluid provides many advantages. Economically, MQL simply costs less. Surprisingly, savings are not simply from buying less fluid. Although MQL fluids typically cost substantially more per gallon, less than 1/10,000 of the amount of fluid is used, making the cost per machined volume much less. MQL is considered a near-dry process, with less than two percent of the fluid adhering to the chips. This is not the same as dry machining, where no fluid is used, but both share the characteristic of needing no reclamation equipment. This eliminates investments into sumps, recyclers, containers, pumps, and filtration devices. There are also no costs for cleaning and drying the chips before their disposal or cleaning the workpieces prior to the next process.

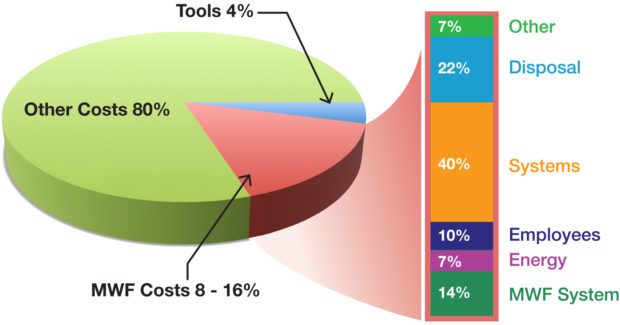

The exact amount of savings varies by plant, but industry estimates are that from 8 percent to 16 percent of total operation costs are related to metalworking fluids (MWFs) – and MQL substantially cuts these costs. The extreme reduction of fluid greatly reduces health hazards caused by MWF emissions, both into the air and onto the skin of employees. When done properly, MQL fluids do not spread throughout the work area, do not get into the electrical components of the machine, nor dissolve the paint off surfaces. The whole shop is cleaner and the life of the machines is extended. Although it may seem counter-intuitive, many shops see substantial increases (reports up to 500 percent!) in tool life due to a reduction in the thermal shock that the tool experiences in the cutting process. Along with improving tool life, surface finishes are usually better as well. Many shops also increase throughput rates because higher feeds are often used with MQL. Heat transfer is more of a factor with MQL than conventional machining. The increased feed reduces the heat in part by minimizing the time the tool and chips are in contact with the part.

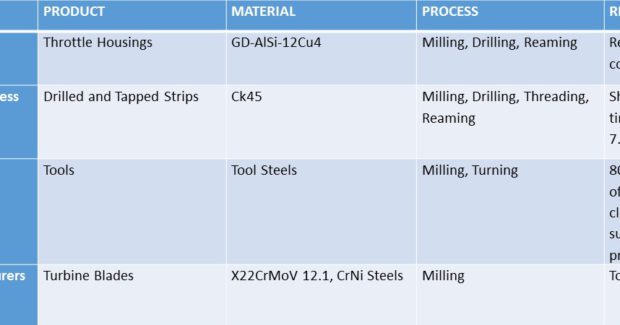

Lastly, in comparison to flood coolant, MQL is better by far for the global environment, reducing waste and using eco-friendly fluids. What is really exciting about moving to MQL is the virtuous cycle it starts. All of the elements work with each other to reinforce the positive results. A three-year project called “Research for Tomorrow’s Production” by the German Ministry of Education and Research (BMBF; Bonn, Germany) examined MQL and other “dry machining processes” (defined as those that leave less than two percent fluid residue on the chip) through 58 studies involving Bosch, Daimler-Chrysler and several other manufacturers using many different materials (see Ex. 1).

A REAL OPPORTUNITY

While stronger environmental laws have led to more widespread adoption in European countries, MQL is not as widely known or understood in North America – this is bad news for U.S. manufacturers, because these international competitors have invested the time, learned the hard lessons, and are now reaping the advantages of MQL. By failing to investigate MQL, American manufacturers may be missing “the next real technology opportunity to restore American manufacturing leadership,” according to Doug Watts, the chief technology officer of MAG Automotive, LP (Sterling Heights, MI), writing in a Views column by the Technical Issues Committee of AMT (McLean, VA).