Highly Productive Machining of OCTG Parts

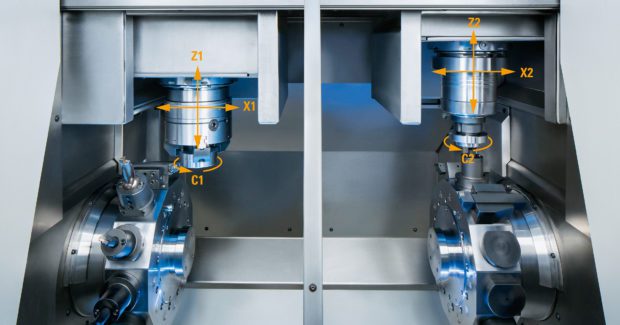

The twin-spindle VL 3 DUO turning center from EMAG is ideal for machining precision metal components used in oil country tubular good applications.

Posted: January 18, 2019

In Booth 2321, EMAG LLC (Farmington Hills, MI) will feature manufacturing systems for precision metal components, with a special focus on the creation of OCTG components. On display will be their VL 3 DUO multi-spindle machine for highly productive turning of chucked parts. This twin-spindle system is perfect for machining chucked parts up to 6 in diameter, and integrates all of the most recent technological developments, including self-loading spindle, the TrackMotion automation system and a modular machine design. With all of these innovations, the VL 3 DUO is the highly productive while maintaining a minimum footprint.

EMAG LLC, 38800 Grand River Avenue, Farmington Hills, MI 48335, 248-755-9775, Fax: 248-477-7784, www.emag.com.