High Performance Machining of the Most Difficult-to-Cut Materials

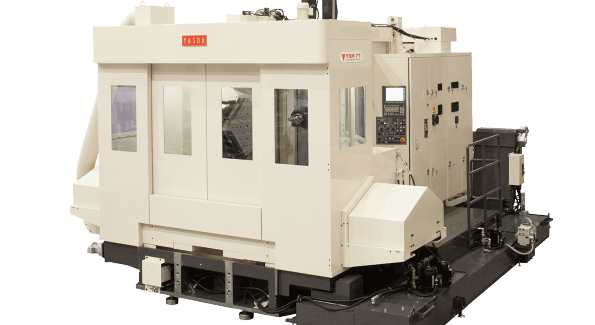

The unique rotary table design and exceptionally rigid machine structure of the YASDA YBM 7Ti 5-axis CNC horizontal jig borer with a two-position automatic pallet changer from Methods Machine Tools is ideal for machining titanium, Inconel and other heat-resistant materials.

Posted: January 15, 2019

The YASDA YBM 7Ti 5-axis CNC horizontal jig borer with a two-position automatic pallet changer from Methods Machine Tools, Inc. (Sudbury, MA) features the industry’s highest accuracy and performance required to machine the most difficult-to-cut materials. Its unique rotary table design and exceptionally rigid machine structure provide high performance machining of heat-resistant materials, such as titanium and Inconel. To ensure extraordinary accuracy levels, this horizontal jig borer has hardened box guideways and a 10,000 rpm, 50-taper direct-drive spindle. The machine is also available with a six-pallet APC. The rotary table on the YBM 7Ti offers four times the rigidity compared to other rotary tables. With its unique table design, there is ample room around the pallet which provides smooth table movements and allows operators to get a closer and clearer view of their parts.

A 25 ton, H-shaped steel machine base absorbs cutting forces and drastically minimizes any machine vibration. All axes have hand-scraped, hardened box guideways for high accuracy when making challenging cuts. Hardened, ground and lapped guideways enable rapid feeds of up to 48 m/min, yielding the highest accuracy throughout every full stroke. To achieve maximum performance levels, the mating faces of the guideways are approximately double the width of more traditional guideways. A direct-drive spindle system keeps cutting forces away from the spindle motor to maintain consistency and repeatability. A YASDA self-adjusting spindle system automatically adjusts the preload to the spindle bearings, enabling a wider range of cutting capabilities.

YASDA horizontal machining centers have a large work envelope with XYZ travels of 49.2 in x 39.4 in x 43.3 in (1,250 mm x 1,000 mm x 1,100 mm) respectively, a vertical rotation of 360 deg and a horizontal rotation of ±110 deg. A two-pallet system has 19.7 in x 19.7 in (500 mm x 500 mm) pallets for a maximum loading capacity of 1,102 lb (500 kg) on each pallet. Maximum part size is 24.8 in (630 mm) diameter and 19.7 in (500 mm) tall. A curvic coupling system with large diameter circle gears is used to support the back side of the pallet, allowing the accuracy of the center of the pallet to be fully maintained. An Automatic Tool Changer holds up to 450 tools. The powerful, new easy-to-use FANUC FS31i-B5 control is furnished standard.

Methods Machine Tools, Inc., 65 Union Avenue, Sudbury, MA 01776, 978-443-5388, Fax: 978-440-9405, www.methodsmachine.com.