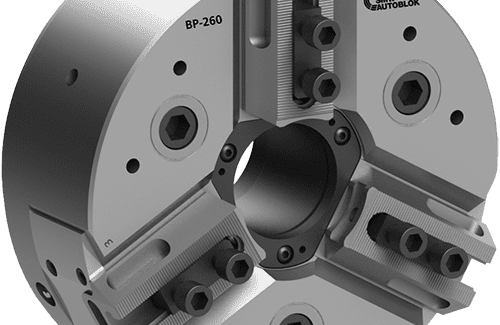

Flexible Sealed Chuck for Bar, Bar Stock and Shaft Clamping

The only sealed chuck of its kind with a large through hole, the BP Series Chuck from SMW Autoblok combines the flexibility of a standard open center power chuck with the long life and precision of a sealed chuck to maintain a constant grip force for excellent repeatability and consistency, as well as safer operation.

Posted: January 17, 2019

The BP Series Chuck from SMW Autoblok (Wheeling, IL) is the only sealed chuck of its kind on the market with a large through hole. It combines the flexibility of a standard open center power chuck with the long life and precision of their Proofline®-sealed chucks, making it ideal for bar and bar stock clamping as well as shaft clamping. Available in three sizes, the BP is completely sealed from outside contaminants, allowing it to maintain a constant grip force for excellent repeatability and consistency, as well as safer operation, whereas non-sealed chucks can lose more than 50 percent of their grip force if not maintained properly.

The BP Series is Proofline-sealed for minimal maintenance intervention. Its permanent grease lubrication provides consistency of clamping force and reduces wear on the chuck resulting in longer maintenance intervals to reduce downtime and loss of productivity. These chucks also hold up in the harsh environments of dry machining, abrasive powders, high pressure or corrosive coolants and more. The BP-D utilizes master jaws with inch serration, while the BP-M operates with metric serration (suitable for Japanese jaws). The American standard, tongue and groove master jaws, are available on the BP-C.

SMW Autoblok, 285 Egidi Drive, Wheeling, IL 60090, 847-215-0591, Fax: 847-215-0594, www.smwautoblok.com.