Choosing the Right Shear for Your Application

Five different types of shear grinds for punch press tooling can reduce the amount of punching force required, increase tool life when side loading is not a concern, and minimize the amount of wear on the machine. Here are some tips on how to choose the correct option for a specific application.

Posted: January 2, 2019

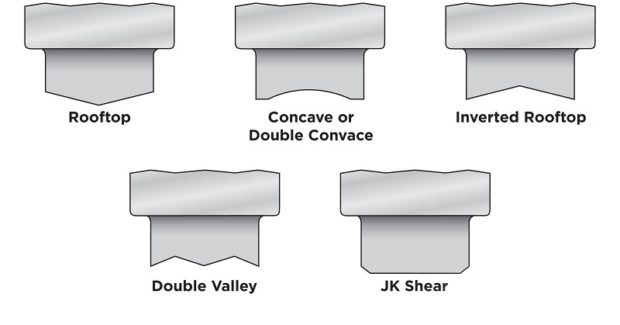

In certain punching applications, adding a shear to the punch can reduce the amount of punching force required. Reducing tonnage not only increases tool life in instances where side loading is not a concern, but minimizes the amount of wear on the machine. There are essentially five different types of shear grinds for punch press tooling. Choosing which of these five shear options to add to your punch depends on the application:

- Rooftop. The rooftop shear is best for punching at maximum tonnages. It can be used for nibbling applications only when the bite is 75 percent of the punch dimension, otherwise excessive side loading will result.

- Concave or Double Concave. For nibbling applications in light gauge materials, the concave or double concave shear is best. This design inverts the stress of punching and minimizes the risk of the punch breaking under higher workloads. Though the concave sweeping radius is not as susceptible to breakage as the sharp point of the inverted rooftop, caution should be used when punching under high tonnage.

- Inverted Rooftop. The inverted rooftop is also a good shear for nibbling applications because it inverts stresses. However, this design is more susceptible to breakage because of a sharp focal point for stresses — use great care when punching at high tonnages.

- Double Valley. When nibbling a shape that is long and narrow, as in the case of slitting tools, consider using a double valley shear. Like the inverted rooftop, this shear is also less resistant to breakage when punching at high tonnages because of the inverted stresses, causing two focal points to bear the brunt of the force.

- JK Shear. The JK shear is a special grind that allows you to punch high strength materials with a reduced risk of breakage. However, this shear can only be used on punches up to 1.000 in (25.4 mm) diameter or ‘A’ dimension. In some applications, the JK shear may lead to an increase in tonnage but reduces sheet distortion.

MAINTENANCE CONSIDERATIONS

Shear punches require sharp edges and need to be reground more frequently than flat punches. Sharpening punches with shear angles can also be more time consuming because multiple surfaces need to be maintained. However, most fabricators find the benefits of using shear punches far outweigh the inconvenience of additional maintenance. Choosing the right shear for your application can reduce the amount of tonnage required, increasing tool life and minimizing machine wear. Less punching force means less recoil which improves stripping and minimizes slug pulling.