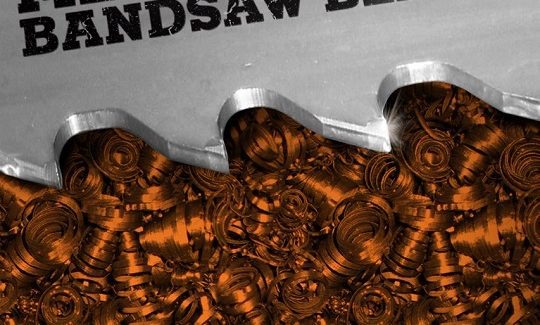

Bandsaw Blade for Cutting High Nickel Alloys, Rene-Type Materials and Super Alloys

Part of a wide range of horizontal and vertical cutting systems for general purpose and production cutting applications from Bahco, the Wavy Bandsaw Blade is ideal for high productivity and improved accuracy in tough cutting applications.

Posted: January 2, 2019

The Wavy Bandsaw Blade from Bahco® North America, Inc. (Kenosha, WI) is a customized blade designed and engineered specifically for tough cutting applications, including high nickel alloys, Rene-type materials and super alloys. The Wavy Bandsaw Blade concept can be applied to any Bahco Bimetal or Carbide Bandsaw Blade. Earning a U.S. patent, this blade features a faster cutting rate and longer blade life that increases productivity and saves money. It also produces more accurate cutting and reduces the risk of premature blade failure due to heat buildup. The Wavy Bandsaw Blade is part of a wide range of general purpose and production cutting applications available in the Bahco Bandsaw Blade Catalog, which features a diverse line of horizontal and vertical cutting systems along with cost-reducing guidance for a variety of manual labor professionals and general-purpose bandsaw users.

Product profiles in this catalog detail an array of systems designed and engineered to increase productivity and provide cost savings, while detailed guides and selection charts help users identify the right solution for a variety of materials, including steel, piping, rods, hard-to-cut alloys and more. Besides Wavy Bandsaws, other blade types featured in this catalog include Pallet Dismantlers, Sandcut® Bimetals (3861), Sandflex® (M42/P9000), Easy Cut® (3857), Cobra™ (3851), TOP Fabricator (3853), KING Cobra™ (PHG MKIII/PQ), Multi-chip and Triple Chip Unset Carbide Tipped, Carbide Triple Set® (3868/3869) and Carbide Triple Set® “Xtra”™ (3868). In addition to accessory listings that include chip brushes, measuring tools and safety equipment, this catalog provides additional assistance to aid users with the purchasing and ownership experience:

- Tooth Pitch Selection Chart and Speed Selection Guide

- Feed rate/chip insights

- Chip load per tooth formula

- Cutting pipes and profiles selection diagram

- Technical Resources and Troubleshooting Guide

For more information on the Wavy Bandsaw Blade and the Bahco Bandsaw Blade Catalog, contact your local Snap-on Industrial Brands or Snap-on Industrial sales representative.

Bahco North America, Inc., Snap-on Industrial division of Snap-on Incorporated, 2801 80th Street, Kenosha, WI 53143, 877-762-7664, [email protected], www.snaponindustrialbrands.com.