The Machine Tool as a CMM: Live Simulation of Measurement with Feedback to Improve Machining

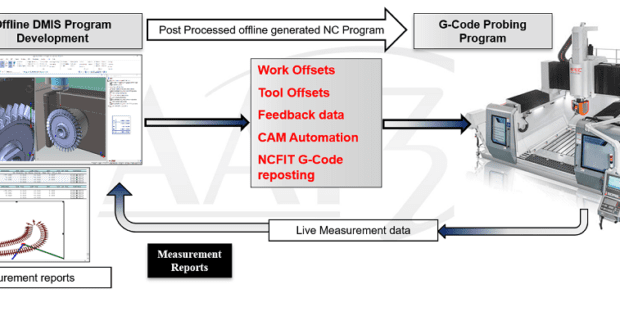

CappsNC software from Applied Automation Software allows programming offline and runs any CNC machine tool as a CMM by using integrated measurement data to automatically improve the machining process.

Posted: December 11, 2018

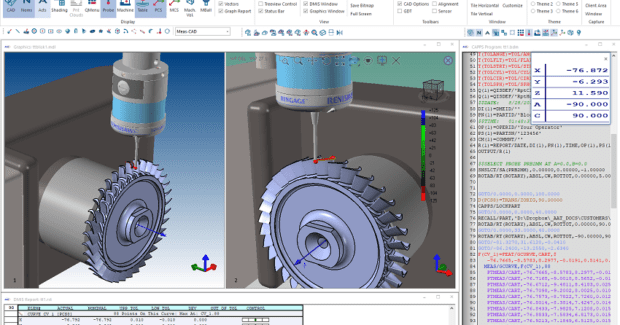

To perform the complex mathematical calculations required for metrology-based real-time adaptive control of CNC machining processes, powerful coordinate measuring machine (CMM) software needs to be directly integrated within the manufacturing system. CappsNC from Applied Automation Software, Inc. (Rochester Hills, MI) is an adaptation of CappsDMIS CMM software that has been developed for programming any machining center to perform advanced measurement, metrology and GD&T calculations using the standard DMIS language. Powerful offline programming, with automatic collision avoidance and 5-axis path generation, allows programming of all machine configurations, including multi-axis mill-turn machines:

- Offline Programming. A CAM-style programming environment with realistic machine tool virtual model, simulation capabilities, automatic path generation with collision avoidance and complete geometrical fitting and tolerancing functionality are embedded within the CappsNC programming environment. Multi-View graphics with an intuitive UI programming environment makes it very simple to create measuring programs for any machine tool configurations.

- Online Execution. CappsNC connects with a comprehensive library of machine tool controllers to provide a real-time direct interface. A G-Code program is generated from the DMIS measuring program that allows the machine tool to be used just as regular machining programs by the operator or as an automated cycle. The software graphics display live 3D simulation of the measurement process, with calculations performed as soon as measured data is collected. The calculated metrology characteristics, such as best-fitting the data-set to a CAD model, are integral to the ‘on-the-fly’ decision making and written back to the machine tool controller as a part of the adaptive control cycle.

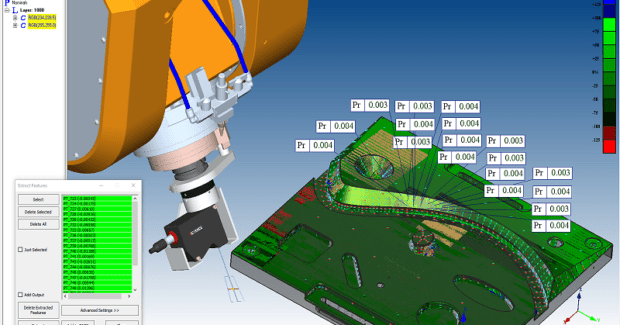

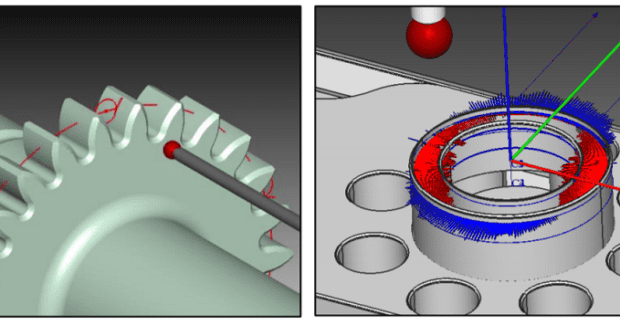

- Multi-Sensor software. CappsNC is independent of measuring probe brands, using its own generated macros to work with the existing installed machine tool probes. This multi-sensor measuring software operates with kinematic and strain gage touch probes, analog scanning probes and laser line probes. The software generates vector-based probe calibration to compensate for any lobing errors of kinematic triggering mechanisms. Automatic calibration cycles are generated to calculate probe run-outs, effective radius and 5-axis head offset errors, eliminating the need to independently preset the probes and providing a quick check any 5-axis head machine misalignment.

Automatic contact scanning paths are generated for any part geometry, curve or surface measurement, such as airfoil or gear profiles. Advanced data filters and automatic comparison to CAD models, with 3D best-fit algorithms, allow quick calculation of characteristics for on-machine automatic decision making. The advanced point-cloud functionality of the software allows on-machine high density data collection using a blue light laser-line sensor. Laser scan programs are automatically generated by converting NC cutting programs or directly from CAD models. Automatic geometric feature extraction provides very quick data analysis for reporting or G-Code program adaptation to the actual part geometry. CappsNC allows the operation of any machining center as a CMM, but the user advantages can be much larger than simply performing on-machine measurements. Other benefits include:

- Pre-Process – Quick monitoring of the machine tool geometry by using an artifact; advanced 6DOF part alignment and work offset creation; re-posting of 5-axis NC programs for non-rigid parts, such as composites.

- In-Process – Dynamic cutting tool offset and wear compensation measures and provides feedback for actual cutting tool shapes during machining process; automated decision making based on measurement results.

- Post-Process – Elimination of moving parts back and forth between machine-tool and CMM; create complete measurement reports including graphical displays and server data archiving and traceability; SPC analysis and process charts.

Applied Automation Technologies, Inc., 1688 Star Batt Drive, Rochester Hills, MI, 48309, 248-656-4930, Fax: 248-413-6037, [email protected], www.aat3d.com/manufacturing.