The Dream Machine: Fully Automated, Nearly Autonomous Laser Processing

Ideal for Industry 4.0, the fully automated TruLaser Center 7030 from TRUMPF works autonomously over long periods, without any operator intervention for programming all the way to sorted and stacked finished parts. It eliminates collisions involving tilted parts, refinishing work on microjoints, spatter on the undersides of components, and excessive programming work.

Posted: December 11, 2018

The new TruLaser Center 7030 from TRUMPF Inc. (Farmington, CT) is a fully automated laser processing machine that takes care of production nearly autonomously. It offers extremely efficient, automated, and synchronous processes, from programming all the way to sorted and stacked finished parts. The machine works with a hybrid drive system to meet the ambitious goal of eliminating all obstacles during the laser cutting process, including interruptions due to collisions involving tilted parts, refinishing work on microjoints, spatter on the undersides of components, and excessive programming work. The TruLaser Center 7030 moves the sheet and the cutting head simultaneously, and the slats have been replaced by brush tables. The machine, which is almost entirely automatic, ejects small parts safely and sorts them into eight containers, disposes of dust and slag, sorts and stacks larger parts during processing, loads itself with blank sheets, and stacks scrap skeletons.

Numerous innovative and patented solutions contribute to the coherence of the entire system. “We were gradually having to face more and more calls for help from our customers, asking us for solutions that would create a reliable overall process,” explains Heinz-Jürgen Prokop, the head of development and procurement in the TRUMPF Machine Tools division. “It turned out that this wasn’t possible with the machine concepts we already had, so a complete re-think was required.” The TruLaser Center 7030 works with a 6 kW TruDisk solid-state laser. When it comes to cutting productivity, the machine is on par with high-end machines equipped with flying optics, even though the sheet, with its relatively high mass, is moved precisely over the brush table in the Y direction. This was made possible by two solutions: First, the sheet – a maximum of 60 in by 120 in – is moved across the short side. Second, the cutting optic, which moves mainly in the X direction, has an additional axis in the Y direction which travels about 2 in. With smaller contours, only small masses need to be accelerated, enabling high dynamics.

On this hybrid machine, the support table for the sheet must be divided beneath the path taken by the cutting head. This creates a gap where the laser beam can escape downwards, but through which slag, slugs and cutting gas is also extracted. To prevent any sheet contours from getting caught there, as well as enabling a far more efficient exhaust system, the SmartGate was invented: two gates which move simultaneously below the material, in sync with the cutting unit. They can also change their distance from each other to create different-sized gaps. This results in two major benefits: The sheet is securely supported during the cutting process, and small parts measuring up to 6 in by 6 in can be ejected and sorted downward in eight separate user specified bins.

To ensure maximum process reliability, an ejector cylinder has been attached to the cutting unit that presses the sheet metal parts downward into the Smart Gate. The programming system, TruTops Boost, automatically calculates the ideal ejector cylinder contact point to suit the respective part contour. Since the Smart Gate slides below to form a counter-support under the sheet, the workpiece cannot tilt or tip. Scrap and slag fall directly into the scrap cart or are transported out of the machine on a conveyor belt. The finished parts are intercepted by a retractable sorting flap and the SortMaster Box Linear distributes them into a maximum of eight containers.

For the automatic removal of the large parts from the scrap skeleton, the SmartLift and SortMaster Speed represent an intelligent, completely new and, above all, reliable process solution. With one stroke on the SmartLift, the laser cut parts are lifted from the scrap skeleton via a total of 180 freely-positioning pins located under the sheet. Each individual pin can lift up to 22 lb, making the process far more powerful than today’s suction systems. At the same time, the SortMaster Speed secures the part from above with its suction plates, ensuring precise linear guidance during lifting. As a result, any risk of parts tilting into the kerf can be safely ruled out. The two telescopic arms on the SortMaster Speed are each equipped with three suctiohttps://youtu.be/Y1KYc7Aptmgn plates and can sort and stack parts onto a maximum unloading area of 5 ft by 15 ft.

TruTops Boost calculates the optimal position of the pins and suction plates automatically – enabling the removal of very large parts, as well as smaller ones no larger than a credit card. Even highly complex or very complex geometries – considered impossible to remove mechanically until now – are lifted safely from the sheet, without the need for any manual programming. The strategies for removing and cutting the parts are coordinated in such a way that the machine continues to cut while the parts are being transported away. Today, productivity per unit area is important and the TruLaser Center 7030 has three powered drawer-type carts that can be extended as far as the aisle. Pallets with stacks of blank sheets up to 5 in tall and weighing a maximum of three tons can be placed onto the middle cart from the aisle by forklift trucks. There is also a cart for scrap skeleton stacks up to 10 in tall that transports pallets from the machine. Separating, lifting and insertion of the blank sheets into the clamping unit takes place automatically, parallel to unloading of the scrap skeleton.

The numerous options and the synchronized interplay of the individual processes make near-fully automatic programming indispensable. In fact, the TruLaser Center 7030 operates almost as simply as a printer in an office: send it a document with corresponding job data – geometries, quantities, material types, thicknesses – and it provides the finished parts, sorted and stacked to suit the order. This includes nesting of the parts on the sheet, assignment of cutting technologies, removal strategies, placement of cut parts onto the storage shelves, and ejection into the container. Here, the SmartGate, ejector cylinder, pins, sorting flap and SortMaster Speed do not have to be individually programmed. Simulations running in the background factor in the component geometry and material characteristics, ensuring an optimal calculation result. They are supported by the clearly laid-out order management of the TruTops Boost programming software. As a result, programming takes place in one single step automatically, but can be adjusted interactively at any time.

The TruLaser Center 7030 works autonomously over long periods, without any operator intervention, and is also equipped with all the necessary interfaces and functions. This makes it an ideal machine for Industry 4.0 and TruConnect systems. Its Dot Matrix Code supports connection to various processing technologies and creates transparency during part tracking. The TruLaser Center 7030 addresses sheet metal fabricators from all sectors who cut sheets from .04 in to 1/2 in thick at high capacity. This fully-automatic laser cutting machine reveals its potential from the very first shift onward. With a two-shift operation, processing costs are as much as 30 percent lower compared to standard automated machines with solid-state lasers.

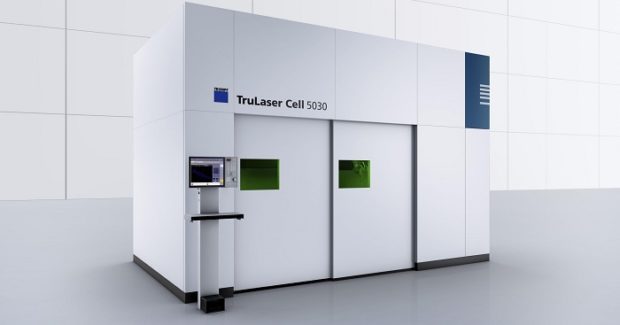

TRUMPF also introduces their new TruLaser Cell 5030, a system specialized in prototypes and low-to-medium volume production. Neatly positioned between the highly productive, high-end machines of the TruLaser Cell series 7000 and the small to medium-sized component processing of the TruLaser Cell 3000, the TruLaser Cell 5030 comes with a TRUMPF disk laser as standard, making it a rugged, low maintenance and energy efficient choice. As well as offering an excellent system for bridging the gap between 2D and 3D laser processing, the TruLaser Cell 5030 is also a worthy successor to the many older models of hybrid machines still equipped with CO2 lasers that are destined to make way for a new generation of machines in the medium term. The engineers who developed the TruLaser Cell 5030 have created a reasonably priced system that uses modern technology to deliver excellent cutting results.

The TruLaser Cell 5030 is equipped with flying optics, a system where the laser processing head “flies” across the stationary, clamped part, machining programmed points along the way. Flying optics keep the process consistently accurate, regardless of the weight and position of the part. Combined with the solid-state laser, improved part performance and highly dynamic axes yield impressive high productivity gains of 200 percent compared to typical hybrid machines, while saving 50 percent in operating costs. The TruLaser Cell 5030 is equipped with the same control system as the other machines in this series. The TruTops Cell Basic software offers multiple features, including the ability to modify design parameters through the machine interface itself. This reduces the time it takes to set up the production process, which is particularly beneficial for small batches. The system also includes numerous preset cutting tables that reduce machine set-up times for different materials and material thicknesses.

Another feature that keeps things running smoothly is X-Blast, a technology that almost doubles the working distance between the nozzle and the workpiece to make the cutting process significantly more reliable and robust. As well as improving nozzle life, X-Blast also helps to ensure high-quality cut edges even with challenging 3D contours. Another user-friendly feature is the FocusLine function that automatically tailors the focal position of the laser beam to the type and thickness of material.