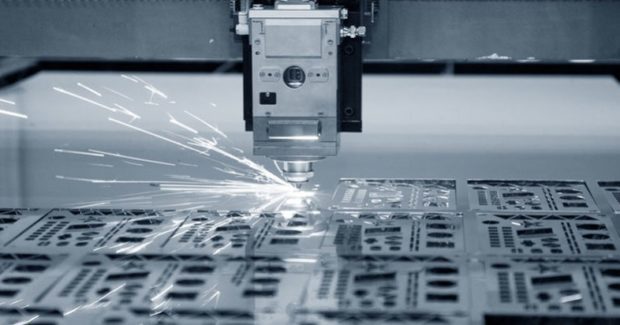

Shop Uses Tabs to Save Five Hours on a Single Laser Run

Laser Cutting Services used the recessed tabbing feature in SigmaNEST software from SigmaTEK to save five hours of secondary process time deburring each part post-cut on a run of 4,000 parts.

Posted: December 11, 2018

As tariffs and shifting market conditions drive metal fabricators to become even more competitive, SigmaNEST software from SigmaTEK Systems, LLC (Cincinnati, OH) delivers features and ongoing enhancements that are required to drive capacity, increase competitiveness and optimize processes. For example, its recessed tabbing feature for laser processing is used by Laser Cutting Services, Inc. (LCS; Tualatin, OR) on various complex parts and in one laser run of 4,000 parts, saved the shop five hours of secondary process time deburring each part post-cut. With this time savings, their long-time customer can receive their parts more quickly and LCS instantly increased both their capacity and profitability while still remaining very cost competitive.

The importance of tabs becomes more evident as nesting jobs proceed. Jobs begin with one part: the sheet. Secured to the workstation, the nesting and cutting process turns one sheet into multiple independent parts, each degrading the integrity of the sheet. Forces from the machine, tool, stock, and parts all have the potential to impact job quality. As the number of fully cut parts increases, forces intensify and create errors in remaining machine operations. Recessed tabbing maintains sheet integrity by leaving it in one piece, keeping forces consistent throughout the job. Cutting as many quality parts per sheet as fast as possible is critical in today’s competitive market. Increasing the laser machine capacity of fabricators also increases their profitability. The faster the work gets done, the more billable work fits in a day.

Laser Cutting Services, Inc., 12475 SW Herman Road, Tualatin, OR 97062, 503-612-8311, www.lasercuttingservices.com.

SigmaTEK Systems, LLC, 1445 Kemper Meadow Drive, Cincinnati, OH 45240, 513-674-0005, www.sigmanest.com.