Predictive Maintenance Waterjet Pumps and High Definition Plasma Cutting

HyPrecision predictive maintenance pumps from Hypertherm are a first for the waterjet industry, and their new XPR170 is one of only two X-Definition capable plasma cutting systems in the world.

Posted: December 8, 2018

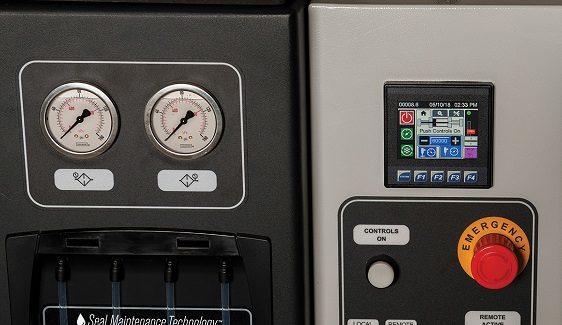

Hypertherm Inc. (Hanover, NH) introduces the industry’s first predictive maintenance waterjet pumps to substantially reduce maintenance costs and disruption caused by non-planned service. This new generation of pumps – called HyPrecision Predictive – are equipped with features such as the proven Advanced Intensifier Technology and new patented technologies, like closed loop proportional pressure control that adjusts for pressure and temperature, oil viscosity, and hydraulic system wear parts; along with technology that enables customers to use seals up to 40 percent longer. In addition to technologies to increase performance and reduce system downtime, HyPrecision Predictive pumps are designed for ease of service, with features such as a color-coded junction box, electrical cable harnesses, quick-disconnect fittings, and an easy access bleed-down valve all make maintenance faster and less expensive.

HyPrecision Predictive systems are also designed for safety: a clear window cover lets the operator see the intensifier and attenuator. Optional electrical interlocks prevent unauthorized access and can automatically stop the pump when opened. Finally, Seal Maintenance Technology™ helps keep the top deck and shop floor free of oil and water. HyPrecision Predictive pumps are available now in six different models, ranging from 15 hp to 75 hp.

Hypertherm has also introduced a new X-Definition™ class plasma – the XPR170 – to the North American market. This new 170 amp system joins the XPR300 as the only two X-Definition capable systems in the world. A combination of engineering advances and refined high definition plasma processes help X-Definition class plasma deliver unmatched plasma cut quality on mild steel, stainless steel, and aluminum. Laboratory testing shows ISO-9013 Range 2 cut quality on thin mild steel and extended ISO Range 3 cuts on thicker metals. The XPR170 contains several new patent-pending processes, such as Vented Water Injection™ (VWI), plasma dampening, and vent-to-shield technologies for squarer cut edges, markedly less angularity, and excellent surface finish on non-ferrous metals like aluminum and stainless steel. It is ideally suited for cutting thin to mid-range thickness metals. At the same time, this system cuts faster and uses power more efficiently.

Consumable life and cut quality over the life of the consumables get a dramatic boost from advances such as Cool nozzle™ and Arc response technology™, the latter of which protects consumables from the negative impact of ramp down errors, a regular occurrence in real-life cutting. By reducing the impact of ramp down errors, XPR consumables can last up to last three times longer than on competitive, older generation systems. “Even experienced fabricators are surprised by the precision they are seeing, and excited by the prospect of using plasma – with its lower initial investment cost – in lieu of laser,” noted Phil Parker, the product manager for the XPR line of plasma systems.

Hypertherm Inc., PO Box 5010, Hanover, NH 03755-3124, 603-643-3441, www.hypertherm.com.