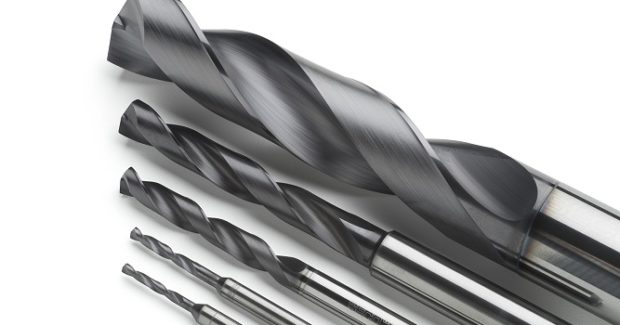

How to Generate More Holes Faster and with Fewer Required Drills

Combining new geometry and new coating with strong point geometry, the Feedmax –P drill from Seco Tools lets shops run machine tools to their full drilling potentials.

Posted: December 5, 2018

With a new geometry and new coating, the Feedmax –P drill from Seco Tools, LLC (Troy, MI) enhances chip management and delivers high application security that allows shops to generate more holes faster and with fewer required drills. The Feedmax –P features strong, straight cutting edges, and the drill’s coolant holes are in close proximity to the cutting edges for more efficient cooling. Narrow land margins minimize the heat exposed to the drill, while an enhanced flute design protects drill point corners and maximizes the control and evacuation of chips. With its dark-colored TiAlN coating, this drill lets shops run machine tools to their full drilling potentials. Together with the drill’s strong point geometry, cutting speeds of 190 m/min are possible in SMG P5 without sacrificing tool life. The Feedmax –P is available in diameters ranging from .0780 in to .787 in (2 mm to 20 mm) and in length-to-diameter ratios of 3xD, 5xD and 7xD. Internal coolant supplies come standard to ensure maximum performance. Custom versions such as intermediate sizes and chamfer and step drills are available upon request.

Seco Tools also offers Crownloc™ and Crownloc Plus exchangeable tip drills that not only produce high quality holes but also lower cost by eliminating the need for regrinding. They feature a unique clamping design with a precision-ground interface of interlocking V-grooves to allow high cutting speeds and ensure rigidity and exact positioning repeatability when exchanging crowns. Long land margins provide excellent guidance to ensure precision, while a self-centering geometry eliminates the need for center drilling operations. Double coolant holes through the crown channels high volumes of coolant to the cutting edges resulting in safer and more efficient chip evacuation as well as longer tool life.

Crownloc Plus is the latest generation design and features a strong drill body design, secure locking interface with deep and wide flutes and a polished body. Its crowns have an optimized geometry for improved chip formation and enhanced entering capability. The combination of a TiAlN coating, low-friction TiN coating on the exchangeable head and 10 percent micrograin substrate serve together to increase toughness and wear resistance, while reducing the potential for edge build up. This results in increased output, higher process security, reduction of tool inventory and elimination of regrinding costs.

Both drills are available in optimized tip geometries for different applications and workpiece materials. Crownloc is offered in P geometry for drilling in steel, K geometry for cast iron and M geometry for stainless steel, hardened steel and superalloys. Crownloc Plus is offered in P geometry as a strong and versatile solution across a range of different workpiece materials and M geometry for high temperature alloys, titanium, titanium alloys and stainless steel. Crownloc is available in a diameter range from 0.393 in to 1.023 in (10 mm to 25.99 mm), with other dimensions available on request. Diameter range for the Crownloc Plus is 0.472 in to 0.783 in (12 mm to 19.9 mm).

https://youtu.be/UqP9qncyYoM

To optimize boring operations, Seco Tools offers an expansive range of radial-type tools, including EPB™ 750 heads for rough boring and the EPB 780 units for fine boring. EPB 750 rough boring heads offer the highest possible performance. Available with Graflex™ and Seco-Capto™ connections, these A750 rough boring heads use strong twin cutters designed for high metal removal. They enable geometric hole precision starting from cast, flame cut or drilled holes. The EPB 750 range includes both 90 deg and 80 deg lead angle insert holders, along with a large range of insert grades for all materials. It has a diameter capacity of 0.7 in to 8.07 in (18 mm to 205 mm) with only eight boring heads. The EPB 780 range is designed for all types of fine boring operations and allows for precision adjustments within microns. The insert holder and head contact protect the micrometric diameter setting on these tools for increased reliability. These factors combine to produce hole tolerances down to IT5 with excellent surface finishes.

Ideal for low-to-average machine speeds, the EPB 780 line covers a 0.590 in to 8.070 in (15 mm to 205 mm) diameter range and includes nine pre-balanced cutting heads. EPB 780 fine boring heads are available with Graflex and Seco-Capto connections. EPB 780 heads are dust proof and never require any re-greasing, which helps promote long tool life. These coolant-through heads come in three insert holder sizes and a large range of insert grades to accommodate a wide variety of workpiece materials.

Seco Tools has also re-engineered their Perfomax indexable insert drill with innovative flute designs that deliver higher drilling parameters and longer tool life, as well as provide exceptional chip control and evacuation. The new Perfomax flutes feature improved helix angles along with special anti-friction surfaces and an engineered wave pattern that minimizes contact between chips and flute surfaces. The drill generates shorter chips that evacuate quickly and easily to significantly reduce the risk of chip jamming for higher application security. The fronts of the Perfomax flutes are laser-hardened for added strength, stability and accuracy. A hardness of HRC 60 allows the drill to withstand chip erosion for much longer periods of time, resulting in up to 140 percent longer drill body tool life. The reengineered design of this drill also features a bigger radius at the bottom of the drill’s insert pockets for added rigidity.

In tandem with Perfomax, DS2050 and DS4050 insert grades are especially well suited for heat resistant materials like titanium and titanium alloys. These grades enhance productivity and extend tool life thanks to recently developed free-cutting MP and MC geometries. DS2050 are inserts used for periphery cutting and DS4050 inserts are for center cutting. Perfomax drill bodies are available in diameters ranging from 0.594 in to 2.375 in (15 mm to 59 mm), with length-to-diameter ratios of 2xD, 3xD, 4xD and 5xD and in most spindle interfaces.

Seco Tools also offers their Precimaster™ Plus indexable head system and Nanofix™ solid carbide reamers to boost speed, stability and versatility for more precise, cost effective hole production. Precimaster Plus is a modular reamer system that features an innovative high precision connection, solid-carbide disposable heads as well as common holders for blind and through-hole applications. The system’s patented connection ensures reamer head exchanges are fast and easy with repositioning repeatability and runout of under three microns. A special three-vertical-drive-pin design enables the connection to handle high levels of transmissible driving torque. Internal axial clamping forces draw the reamer heads up into the system shanks, creating a strong interface that maintains high precision. Precimaster Plus disposable heads are offered in diameters that range from 0.390 in to 2.360 in (10 mm to 60 mm) and mount to four standard shank sizes: short, medium and long shank length options accommodate restricted clearance situations, common hole depths and up to 10xD, respectively.

https://youtu.be/N6WDQsD_Tn0

When compared with traditional brazed-tip technology, solid-carbide heads allow for an increased number of cutting teeth on the same head diameters for up to 30 percent faster feed rates. Solid carbide also extends tool life by up to 30 percent, delivers increased stability for tougher materials and makes for a more cost-effective system. For chip control and management, Precimaster Plus reamer shanks can apply different types of flushing for both blind and through holes. Tool body coolant outlets in the front force the chips up along the head flutes and out the blind holes, while standard through-tool coolant blasts the chips forward and away from the tool for efficient through-hole reaming.

Precimaster Plus features three lead geometries for universal, aggressive feed and fine finish operations as well as five reamer head grades, involving coated and uncoated carbide and cermet, to ensure optimized performance in all workpiece materials. The versatile Nanofix solid carbide reamers feature a patented Quick-Fit clamping system that enables two holders to hold the entire diameter range. This precise quick tool changing system reduces the time needed to change tools and eliminates the need to recheck the overall length and positioning when replacing a reamer. Also, with only two shank sizes only two sizes of Quick-Fit holders are needed, thereby reducing the number of items in stock. Nanofix is designed for small diameters from 0.117 in to 0.474 in (2.97 mm to 12.05 mm) and handles internal coolant with a simple adjustable system that enables the outlet style to be set for either through or blind bore, depending on application.

The Nanofix produces hole quality of IT7. This multi-tooth solid carbide reamer is available in three geometries: EB45, EB845 and EB25. The range includes coated and uncoated grades. Nanofix also comes in a shorter length for lathe and compact applications.

Seco Tools, LLC, 2805 Bellingham Drive, Troy, MI 48083, 248-528-5451, [email protected], www.secotools.com.