In-Process Tool Measurement in Machine Tools

The LC50-DIGILOG laser measuring system from Blum-Novotest shortens tool measurement and testing times up to 60 percent using an optimized beam shape and 30 percent smaller focus diameter for better absolute accuracy.

Posted: December 3, 2018

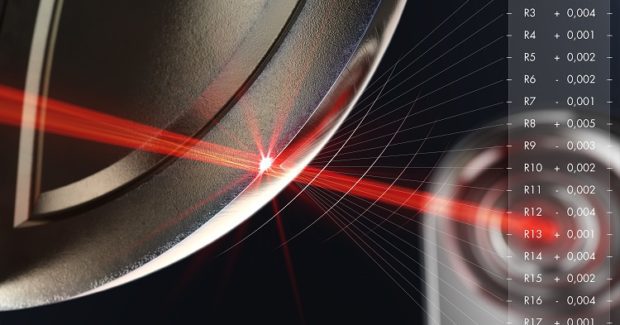

The LC50-DIGILOG laser measuring system from Blum-Novotest, Inc. (Erlanger, KY) is a ground-breaking system that has been completely redeveloped to revolutionize and future-proof the speed, precision and in-process reliability of tool measurement in machine tools. One of the highlights of this system is its newly implemented DIGILOG technology. Whereas proven digital/switching laser measuring systems using NT technology only generate a small number of signals for recording measurements, the new LC50-DIGILOG generates many thousands of measurement values per second. Using this new technology, precision, speed and in-process reliability have been enhanced to a never before imagined level. The compact smartDock represents another breakthrough: this innovative standard interface serves as the basis for all new support systems and contains all of the necessary pneumatic valves, in addition to the electrical, mechanical and pneumatic connections between the machine tool and laser measuring system.

The many new ideas implemented by the developers of the LC50-DIGILOG have resulted in impressive advantages for users. Firstly, measurement and testing times have been shortened by up to 60 percent. In addition, the optics in the system were further improved so that the new generation achieves an absolute accuracy that is better than all comparable measuring systems thanks to an optimized beam shape and a 30 percent smaller focus diameter.

Blum-Novotest, Inc., 4144 Olympic Boulevard, Erlanger, KY 41018, 859-344-6789, www.blum-novotest.com.