Automated Precision Milling of Surgical Instruments and Medical Components

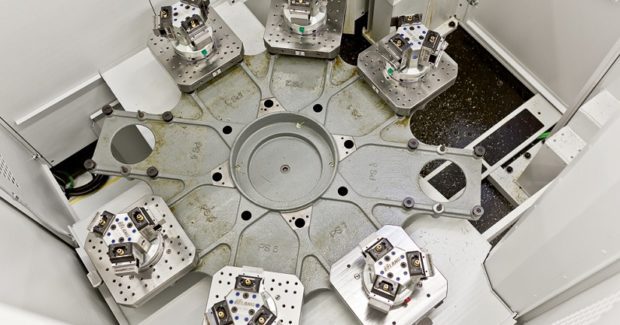

Featuring a 320 mm diameter NC swiveling rotary table with a multi-clamp system, the working area of a high performance Hermle C 22 U 5-axis machining center is used by Fetzer Medical to machine surgical instruments and complex medical components to customer specifications.

Posted: November 6, 2018

Fetzer Medical GmbH & Co. KG (Tuttlingen, Germany) employs tailored yet universally flexible 5-axis machining centers from Hermle AG (Gosheim, Germany) in their role as an OEM partner manufacturing a wide range of surgical instruments and medical technology components to customer specifications. All relevant materials are machined, including titanium, and Fetzer Medical supplies their customers with ready-to-use prototypes/individual parts to large production runs and complete systems. They currently have 45 highly qualified employees and roughly 75 percent of their work involves complex milling/drilling operations on the 5-axis machining centers. “These machines feature a robust gantry design with three axes in the tool and two axes in the workpiece for optimum tool accuracy and excellent accessibility that are ideal for 5-axis complete machining in one or two setups,” explained Bernd Zepf, the production manager at Fetzer Medical.

Fetzer Medical today runs five Hermle machining centers for prompt execution of OEM production orders. Their first 5-axis C 40 U machining center was initially used to cement their manufacturing expertise and add valuable additional know-how, but now it is primarily used for pre-fabrication and machining prototypes, samples and short runs. Two high performance C 22 U 5-axis machining centers are equipped with 11 PW 150 pallet changers/magazines and are used for automated flexible production of a wide range of components in runs of up to 300 pieces. For higher automation, they use a high performance C 12 U 5-axis machining center combined with an RS 05 robot cell for automated machine loading in the production of modular-designed scissors. A C 800 V CNC machining center was added to provide flexible and universal operation in pre-production, including making reference surfaces and jigs and fixtures.

All of these machining centers essentially share the same basic design, the same control and operating philosophy so that operators quickly become familiar with running different machines with high confidence and skill. This increases the single-shift productivity of these machines, except for those with pallets and robots that also run overnight and on weekends. These ‘hard facts’ are complimented by a number of ‘soft facts’ that are essential for the highly complex machining of surgical instruments and medical technology devices: Per EU and U.S. specifications, production and quality assurance equipment must be fully validated and certified in the surgical and medical technology sector. Many U.S. medical manufacturing firms already use validated Hermle machining centers for production, which ensures simpler and faster validation cycles for Fetzer Medical that translates into faster time-to-market for their customers.

Fetzer Medical GmbH & Co. KG, Unter Buchsteig 5, 78532 Tuttlingen, Germany, +49 7462 947990, www.fetzermed.com.

Hermle AG | Hermle Machine Company, 5100 West Franklin Drive, Franklin, WI 53132, 414-421-9770, www.hermlemachine.com.