Ultra-Fast Robots Optimize Spot Welding Productivity

SP-series six-axis robots from Yaskawa America offer ultra-fast axis speeds and improved acceleration/deceleration control to reduce air-cut time and increase production output, with a slim profile to reach into confined spaces for operations in high-density layouts.

Posted: October 16, 2018

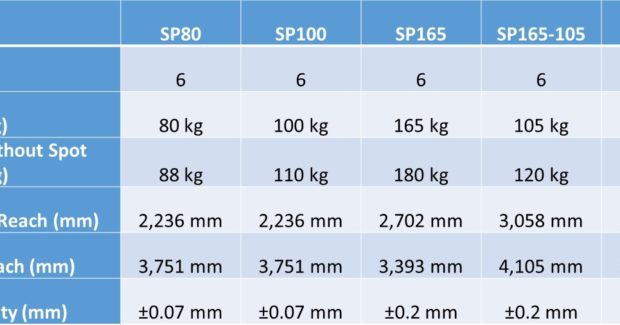

Yaskawa America Inc.’s (Miamisburg, OH) SP-series robots are designed for exceptional spot welding performance and offer ultra-fast axis speeds and acceleration to reduce air-cut time and increase production output. Now available in five models (SP80, SP100, SP165, SP165-105 and SP210), these six-axis robots are powerful and efficient with improved acceleration/deceleration control for all axes to increase productivity. While high allowable moment-of-inertia ratings provide substantial wrist rigidity, a wide wrist motion range eliminates interference and improves application flexibility. A slim profile design allows these robots to reach into confined spaces, facilitating close proximity placement of robots for high-density layouts. An integrated spot harness improves wrist flexibility and reduces downtime for all five robot models as well.

SP-series robots are equipped with servo gun and DC timer technology to optimize productivity and consistent weld quality. Spot monitoring and waveform graphing helps troubleshoot welding conditions, and controller connectivity provides simple wiring to spot timers and robot pendant weld programming for Medar® and Nadex® brand timers. Installation is quick and efficient. A single cable is all that is needed to connect the manipulator to the controller, resulting in easy setup and reduced expenses for maintenance and spare parts inventory. Equipped with an IP67-rated wrist and an IP54 body standard, each robot can be floor-mounted. Uniquely designed for large part processing, the extended reach SP165-105 robot can eliminate the need for a linear track, reducing system cost and simplifying programming. The SP165, SP165-105 and SP210 models do not include a counterbalance, reducing the mass of the robot arm and enabling higher acceleration, deceleration and speed.

SP-series robots are controlled by the high performance YRC1000 controller that is built to a global standard with no transformer required for input voltages ranging from 380VAC to 480VAC. It is highly compact (598 mm W x 490 mm H x 427 mm D) for reduced space requirements.

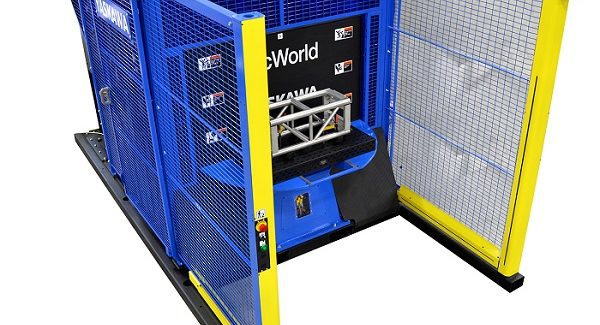

Also on display will be the ArcWorld® 1000 family of pre-engineered robotic arc welding workcells that are faster and more compact than ever. They feature a customer-driven design and standard options proven to optimize small- to medium-sized part production for medium to high volumes. Each model is simple to customize, easy to install and extremely reliable, making it the ideal system for general fabricators, as well as automotive tier suppliers with demanding production requirements. Single robot (ArcWorld 1000) and dual robot (ArcWorld 1200) configurations are available. Both models feature the new six-axis AR1440 robot with a 12 kg payload capacity to support a wide variety of torches and sensors. The robot’s increased speed (over the previous model) enables unrivaled performance and productivity, and the contoured arm design allows easy access to parts in tight spots and avoids potential interference with fixtures.

The AR1440 robot is controlled by the new compact YRC1000 controller that features patented multiple robot control with coordinated motion between devices that allows the AW1200 dual robot configuration to operate from a single teach pendant for optimized control and coordination. This flexible workcell features a high speed servo turntable positioner with either 355 kg or 655 kg capacity. A 1,524 mm or 1,828 mm tabletop is available as well. Maximum part size is 1,000 mm x 474 mm. This “H-frame” style positioner features a protective arc screen that allows the operator to safely load and unload parts from one location outside the robot work envelope while the robot welds inside the workcell. ArcWorld workcells are equipped with a digital welding interface for Miller, Fronius or Lincoln power sources, plus required torch, wire feeder and sensor options. Advanced welding functions, including weld inspection and process monitoring, can be included as an option. EtherNet/IP connectivity is used to connect most peripheral devices and includes a utility to set-up and troubleshoot connections to the robot.

https://youtu.be/goKkQgj-4_I

Each ArcWorld workcell features a total safety environment that is compliant with ANSI/RIA R15.06-2012 (and other international standards). The YRC1000 robot controller includes a Functional Safety Unit (FSU) that uses “stand still” monitoring of the positioner axis while the operator is interrupting the light curtain field. Several standard options are available, including isolation transformers, second enabling switch, tip change box, bulk wire delivery, low wire sensor, gas flow sensor, exhaust hood and a stack light. The compact workcell design has a 4,570 mm x 2,285 mm footprint and fits in a 110 ft trailer. The robot, positioner and safety fence all ship on a common platform to reduce installation and setup time. The controller and power source are shipped attached to the cell base and can be separated for maintenance.

Yaskawa America Inc., 100 Automation Way, Miamisburg, OH 45342, 937-847-6200, www.motoman.com.