One-Stop Portfolio of Coil Processing Solutions

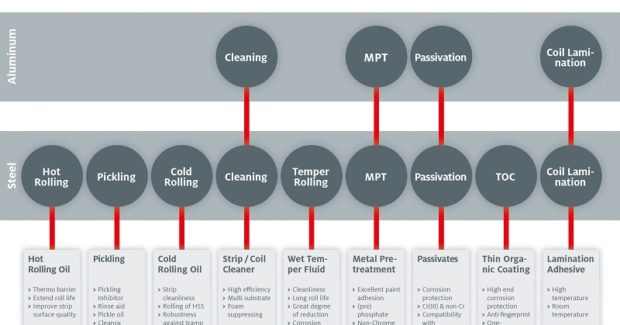

The extensive range of coil processing systems for pickling, lubrication, cleaning, pretreatment, passivation, coating and lamination from Henkel are specially formulated for high speed, continuous operation, greater cost efficiency and sustainability of manufacturing lines.

Posted: October 2, 2018

In Booth B-5036, Henkel Corporation (Rocky Hill, CT) will offer an extensive range of coil processing solutions for pickling, lubrication, cleaning, pretreatment, passivation, coating and lamination that are specially formulated for high speed, continuous operation, greater cost efficiency and sustainability of manufacturing lines. “There is a clear trend in the metal coil industry towards greater process and cost control,” said Aziz Mabrouki, the business director for metal coil in Europe at Henkel. “While new high strength steel, aluminum and magnesium alloys open opportunities for increased lightweighting, sheet metal manufacturers and coaters are faced with ever stricter environmental regulations. We offer them a one-stop portfolio of process solutions to meet these challenges and reduce costs through longer bath and tool lives, elimination of chromium, nitrate in waste water and NOx emissions, as well as reduced waste. We also provide special equipment designed to ensure best manufacturing practices in many coil process steps.”

Their Bonderite™ portfolio of efficient, safe and sustainable solutions for the metal coil manufacturing chain includes:

- Pickling inhibitors added to hydrochloric or sulfuric acid to avoid over-pickling and provide a uniform surface for the next process step.

- Cold rolling oils for best lubrication results that lead to high productivity and high sheet quality.

- Cleaners designed to remove grease, oil and metal fines from the sheet surface to prepare it for the next step.

- Wet temper fluids used to increase the life time of work rolls and provide adequate corrosion protection for intermediate storage.

- Surface treatment agents preparing the substrate for reliable paint adhesion and adding excellent corrosion protection.

- Passivates applied to galvanized sheet and tin plate products to avoid corrosion during storage and transport.

- Thin organic coatings providing anti-fingerprint and other effective properties for decorative surfaces, as well as improved weldability and forming.

Henkel also offers adhesives engineered for reliable and cost-effective coil lamination in compliance with latest environmental regulations. All of these innovative, value-added products deliver higher productivity and extend the lifetime of work rolls during rolling and skin passing, as well as in four key areas:

- Chromium-free formulations for a broad range of more sustainable paint technologies.

- Cost-effective products such as adhesion promoters, Cr-free organic coatings, forming and stamping aids for new alloys and substrates.

- Nitric acid free pickling and solutions for low-fluoride pickling processes to reduce overall operating and waste water treatment costs.

- A full range of pretreatment agents and adhesives for process and downstream cost savings in an increasingly diversified coil lamination market is also available.

“The use of chromium (VI) has already been restricted in Europe, with further prohibitions to come,” added Mabrouki. “We are committed to helping our customers enhance the sustainability of their production by moving to highly effective solutions free of heavy metals and in high concentrations that reduce consumption and waste while optimizing their processes. With a history of 20 years in chromium-free products for painted sheet, we have successfully extended the technology to other processes, such as passivation.”

Henkel Corporation, One Henkel Way, Rocky Hill, CT 06067-3581, 860-571-5100, www.bonderite.com.