Automation Tools, Partnership for Tube & Pipe Fabrication

The innovative and compact UPC 450 Ship Profiler from HGG increases cutting and pre-fabrication productivity by eliminating the need to cut ship stiffeners and spools by hand.

Posted: October 15, 2018

In Booth C-10423, HGG Profiling Equipment (Medina, OH) will showcase their UPC 450 Ship Profiler, an innovative new machine with a small footprint that increases cutting and pre-fabrication productivity by eliminating the need to cut ship stiffeners and spools by hand. UPC 450 production automation combines ship stiffener cutting and 3D profile cutting with optional tube cutting in the first affordably-priced machine of its kind. Having a small machine footprint, it also saves valuable floor space while offering full process cutting integration through the ProCAM Software Suite that merges thermal cutting design, work preparation coordination and exclusive 3D plasma cutting intelligence. The end result: precision stiffener and tubular spool cutting that reduces fitting and welding time and saves labor costs. This versatile Ship Profiler can easily be configured to accommodate a variety of fabrication needs and footprint requirements. One person can quickly and easily convert the UPC 450 from cutting profiles to cutting tubes.

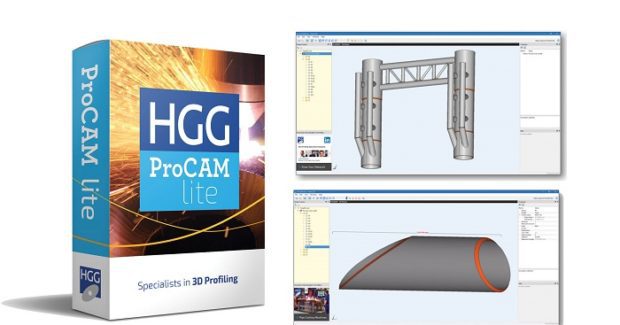

HGG will also be featuring new ProCAM Lite Software, the first software that enables users to view as well as check 3D cutting details on pipes, beams and bulbs prior to cutting – and it is being offered to customers free of charge. Users are not required to have HGG cutting machinery nor any cutting machine to benefit from it and improve cutting productivity. The software currently consists of two program parts, a DSTV viewer and a pipe viewer. To get a free copy of ProCAM Lite software, please click here.

Finally, HGG will introduce their new strategic partnership with global welding and production automation provider Pemamek Oy Ltd. (Loimaa, Finland) that was first announced in April 2018 and was recently extended to include shipyard systems. With the partnership extension, both companies are now able to supply integrated cutting and welding technology, including profile processing lines, pipe cutting lines and T-beam manufacturing lines for ship part fabrication. “They are a global technology and market leader in welding automation,” noted Wiebe Wiersma, the global sales manager of HGG Profiling Equipment BV (Wieringerwerf, The Netherlands). “We are a global leader in 3D profiling equipment solutions. The synergy between our technologies is clear, the integration of solutions is seamless, both mechanically and through our software. With this partnership, both companies are now able to deliver more customer value, while strengthening our combined market presence and client network.”

HGG Profiling Equipment, 3977 Rivendale Drive, Medina, OH 44256, 330-461-6855, hgg-group.com.