How Cardiologists Use 3D Printing to Save Tiny Lives

Pediatric cardiac surgery that deals with delicate structures like tiny little hearts of neonates is one of the most demanding medical specialties. Here is a story about a determined child surgeon, his newborn patient with a heart defect and the child’s mother.

Posted: October 22, 2018

The heart of a newborn child can weigh only 20 grams and fit in the palm of the hand. Medical procedures on such a small organ bring many difficulties. When a heart has only one abnormality, most doctors use CT scans and MRI technology to create an image of the impairment. But the real challenge begins when the heart is tiny, the heart disease is rare or it differs from other typical cases. In all of these examples, even sub-millimeters can make a life-or-death difference. To increase the chance of survival, surgeons have started to 3D print the heart with a laser sintering desktop 3D printer. One example of this is the story of Kordian, a three-week old infant from Poland who was suffering from a heart disease called interrupted aortic arch. “The problem was that the aorta, the biggest vessel coming out of his heart, was suddenly interrupted,” explained Dr. Jarosław Meyer-Szary of the department of pediatric cardiology and congenital heart defect at the University Clinical Center (Gdańsk, Poland).

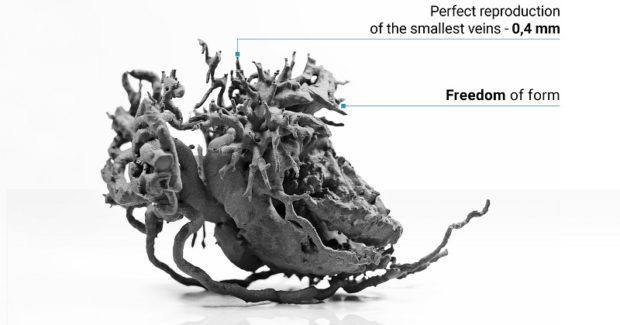

Because this condition could be fatal it presented a threat to Kordian’s life. Both doctors and his mother, a person who had no knowledge about the disease, had to decide quickly about undertaking a procedure. Fused deposition modeling (FDM) has become a popular 3D printing system in many hospitals and is being used by cardiologists to print each heart and assess the abnormality closely. Using FDM, doctors can even perform a mock-up surgery as a simulation before doing the actual procedure. Everyone agreed with Dr. Meyer-Szary about creating and using a 3D printed model of Kordian’s heart in its original size as a support. But unfortunately, while the most common FDM 3D printers are good enough for everyday use, in this case the technology could not help. Dr. Meyer-Szary needed a system that would provide surgical precision to imitate every little vein and artery that surrounds the heart. These veins were either too thin to print using FDM or, because of the needed supports, could be easily torn apart during post-processing.

After doing research, the doctors discovered that 3D selective laser sintering (SLS) technology using an extremely affordable desktop-size Lisa 3D printer from Sinterit could meet all of the requirements. Their latest generation Lisa 3D printer provided an increased Y-axis printing size, with the overall diagonal dimension of the printing area raised from 227 mm to 245 mm, along with hardware enhancements for better temperature management, increased print reliability, improved UX and easier maintenance.

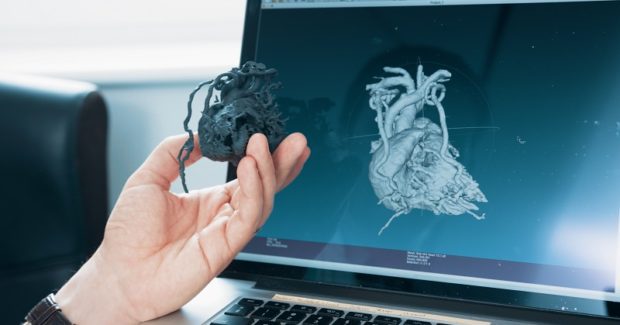

SLS 3D printed models can be used both for planning cardiac surgery and also for interventional procedures, especially in complex and rare congenital heart diseases when the anatomy is always different and varies from patient to patient. The doctors aren’t the only beneficiaries here, because it is also important for the patients and, in this case, parents to understand the situation thoroughly and give permission to operate. “As a head of this department, I sometimes have to explain very complicated congenital heart defects to parents and students who are not doctors or professionals in this area,” noted Dr. Joanna Kwiatkowska, an associate professor at the University Clinical Center. 3D printing helps to plan surgery and makes it safer, easier and shorter: operations where doctors practiced on 3D printed hearts have a higher rate of success and lead to a better life for the patient.

Seeing a scale model of Kordian’s heart made it easier for his mother to understand how serious his condition was and how the procedure should proceed. This made her consent to the operation more conscious than if she only saw a defect on a screen. “I learned about interrupted aortic arch disease when Kordian was three weeks old,” she said. “This model of his heart helped a lot because I didn’t really understand the severity of this heart defect while viewing it on a screen. Touching a printed model helped me realize the seriousness of my child’s disease . . . I could get it. The doctor showed me where the interruption was, presented the defect to me and showed how he would correct it.” Surgeons used the printed model of Kordian’s heart for better planning of the operation. With the interruption clearly visible on the SLS 3D printed model, the minimal size of the heart was not a problem and it helped them to prepare for the complicated operation and they connected raptured fragments of the aorta. “This was difficult surgery, and the model helped them to see the heart more closely than on a screen,” added Dr Meyer-Szary.

Today Kordian is 18 months old, with the happy face and positive attitude of a boy that doesn’t reveal how close he came to death over a year ago.