How to Meet Tough Finishing Demands on Pharmaceutical Projects

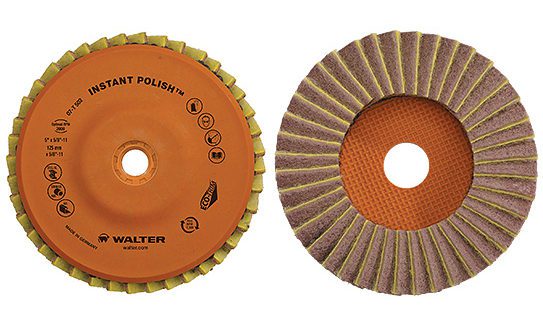

Instant Polish flap discs from Walter Surface Technologies boast powerful polishing properties and superior engineering that easily achieves No. 8 mirror finishes in a single step to save time and money.

Posted: October 29, 2018

To meet the ultra-high performance polishing and finishing demands required in pharmaceutical projects, Walter Surface Technologies (Windsor, CT) presents their Instant Polish™ flap discs for fast, single-step finishes and Ultimate Shine™ flap discs for outstanding, superior mirror finishes on tough polishing jobs. Metalworking shops can attain exceptional polishing results in a single, fast and easy step with Instant Polish flap discs. Now boasting powerful polishing properties and superior engineering, they can easily achieve No. 8 mirror finishes in a single step. As a result, workers can save more time and money. This latest innovation is proven to lower metal roughness averages (Ra) by 20 µin and achieve mirror finishes at Ra of less than 4 µin on tough polishing jobs. “The science, research and product development behind these flap discs is second to none,” explains Jonathan Douville, the senior product manager of Surfox, finishing and coated abrasives at Walter. “They offer longevity and exceptional engineering for consistently high performance polishing in one quick and easy step.”

Instant Polish flap discs are available in 4½ in and 5 in diameter sizes for use at a maximum 7,300 rpm and optimal 2,000 rpm, and offer great performance in pharmaceutical applications, as well as automotive, transportation, food and beverage equipment, aerospace, naval and other sector-specific applications. When ultra-high performance finishing capability is a priority, Ultimate Shine flap discs are a second step towards achieving an exceptional mirror finish. They ensure a consistent surface finish time and time again, delivering definitive mirror finishes with Ra ratings under 1 µin. Long-lasting and versatile, Ultimate Shine flap discs are the ultimate tool to deliver consistent capability on a wide range of finishing projects. They are also available in 4½ in and 5 in diameter sizes for use at a maximum 7,300 rpm and optimal 2,000 rpm. They are safe for use on stainless steel, steel and non-ferrous metals when used with angle grinders.

Walter Surface Technologies, 810 Day Hill Road, Windsor, CT 06095-1790, 860-298-1100, www.walter.com.