Tooling Makes the Difference in Buttress Threading of Stainless Steel

Bent Engineering successfully threaded 60 holes in shale gas blocks made of 17-4PH 900H stainless steel. How did they do it?

Posted: September 5, 2018

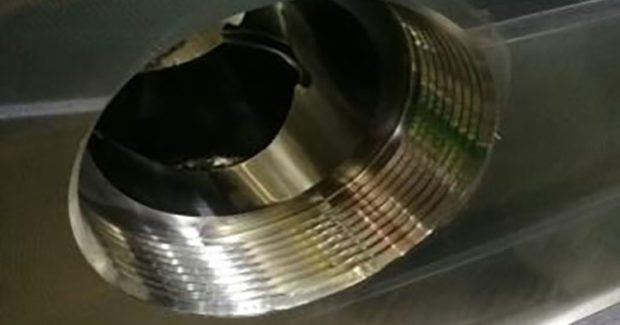

Stainless steels can be one of the more difficult materials to machine, but selecting the proper tooling for the application can make the difference. In a recent project at Bent Engineering (Pohang, South Korea), four separate shale gas blocks made of 17-4PH 900H stainless steel required Buttress threading of 15 holes each for a tight hydraulic seal to handle the transmission of heavy force during operation. Wet machining was successfully performed on all 60 holes using a Doosan DBC130II moving column NC boring machine with a high-torque spindle head for heavy duty cutting.

Tooling selected from Advent Tool & Manufacturing Inc. (Antioch, IL) included a through coolant SMH4015TA8-F8 Helical Shell Mill Holder (4 in cutter), hardened and ground with a 10 deg helix and used with ITH4015-4B7/45-15NR Buttress thread carbide inserts, 1-4 pitch, .250 in thick with a locking angle. Threading each of the 60 holes required four toolpaths cutting at a feed rate of 1.57 ipm at 125 rpm and 131 SFM.

Advent Tool & Manufacturing Inc., 710 Anita Avenue, Antioch, IL 60002, 847-395-9707, Fax: 847-395-9607, [email protected], www.advent-threadmill.com.