Lower Cost Laser Marking of Steel, Aluminum, Stainless and More

The new Laser range from SIC Marking provides great marking quality on steel, aluminum, stainless steel and plastics, and meets 80 percent of application needs at a much lower cost.

Posted: September 28, 2018

The new Laser range from SIC Marking USA (Pittsburgh, PA) uses an exclusive Ytterbium Doped Fiber source, a pulsed operating mode (30 kHz to 60 kHz), a wavelength of 1,064 Nm and an average power of 20 W (available in 30 W and 50 W). These lasers meet 80 percent of application needs at a much lower cost and allows a great marking quality on a large number of materials (steel, aluminum, stainless steel, plastics) and adapts to degraded surface finishes.

Integrated lasers have been developed around two laser sources, a standard EASY version and a HD one, to which are added different options. These features allow every specific need to be met immediately or later on, depending on the user’s production line evolution. In its standard EASY version, this new laser range offers the best quality/price ratio on the market and allows precise marking at high speeds. The HD version (pulse duration from 2 Ns to 200 Ns) provides better marking contrasts on metals, especially aluminum and some plastics. This HD marking head also enables to solve cycle time issues by adjusting the laser’s pulse duration. There are three options to adapt to current and future manufacturers’ needs:

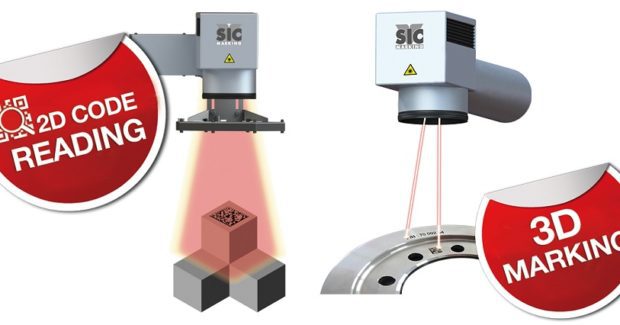

- The first option is 3D marking. It consists of a liquid lens which can mark complex parts (cylinders, inclined planes) or multi-level parts (up to 80 mm difference in altitude).

- Customers can also choose an integrated vision system which includes a high-resolution camera built into the marking head. This function allows to read immediately one or two 2D codes immediately after marking. There is no movement between operations. As the reading is done in the same axis, there is no image distortion. 2D code, QR-Code and Datamatrix markings are checked according to the standards ISO 29158, and ISO 15415, ISO 9132.

- Finally, the laser range also offers the possibility to communicate via Profibus, Profinet and Ethernet / IP field buses.

The modular EASY and HD lasers support industries that need to be responsive to technological developments. “It is important for us to make laser technology more accessible financially to our customers, but also to make sure they pay fair price according to their needs. They have the opportunity to add 3D marking, integrated vision and communication cards options after purchase, because we know that production lines are likely to evolve over time,” stated Jean-Manuel Pauchet, the group managing director of SIC Marking.

The standard laser range is available with marking windows of 60 mm x 60 mm, 100 mm x 100 mm and 170 mm x 170 mm and applies to alphanumeric, datamatrix, barcodes, logos, VIN and QR codes marking. The marking head is easy to integrate on all production lines and can be connected to an industrial network without any additional hardware via digital I/O, Ethernet TCP/IP and RS232. These laser systems operate in standalone mode (without PC) and can communicate directly with a PLC on a production line. Creation and configuration of marking files is done on a PC using SIC Laser Advanced software.

SIC marking USA, 137 Delta Drive, O’Hara TWP, Pittsburg, PA 15238, 1-877-742-9133, [email protected], www.sicmarking.com.