Robust Manual Tool Changer Reduces Changeover Times in Robotic and Non-Robotic Operations

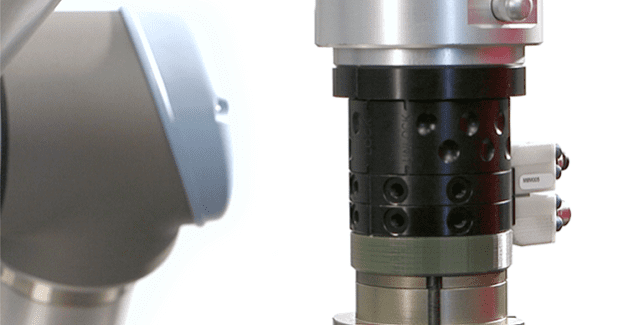

Composed of two mating parts with a high strength-to-weight ratio and low stack height, the MC-10 Manual Tool Changer from ATI Industrial Automation can carry a payload up to 22 lb and enhance the flexibility of automated processes.

Posted: August 24, 2018

In Booth C-11522, ATI Industrial Automation (Apex, NC) will showcase their new MC-10 Manual Tool Changer that is well suited for both robotic and non-robotic applications requiring a quick exchange of tools by hand. Users also have an ,option to pass utilities to their application with additional modules. The MC-10 is composed of two mating parts that are designed to carry a payload up to 22 lb (10 kg) in this case and enhance the flexibility of automated processes. However, the MC-10 includes a few new features that make it ideal for collaborative robot environments. Its ergonomic collar design provides tactile feedback so that users can actually feel a “click” as the unit moves between lock and unlocked positions, as well as visual Lock and Unlock indicators. This tool changer has four integrated airports plus an option to include an electrical module if utilities are required in the application. Several ISO-compatible interface options are available for easy mounting to the robot arm.

The reliability of trusted ATI tool changers has been designed into the MC-10 by way of multiple fail-safe features that resist vibration and prevent loosening. Overall, this tool changer is easy to use but provides secure coupling that ensures no tools will be dropped. Its high strength-to-weight ratio and low stack height makes it an extremely robust yet compact manual tool changing system. For both robotic and non-robotic tasks where tools are presented to a person or process, it facilitates safe, efficient, repeatable exchange of tools that decrease changeover time and equipment needs.

ATI Industrial Automation, 1031 Goodworth Drive, Apex, NC 27539-3869, 919-772-0115, www.ati-ia.com.