Nesting Software Increases Productivity of Flat Sheet and Tube Cutting

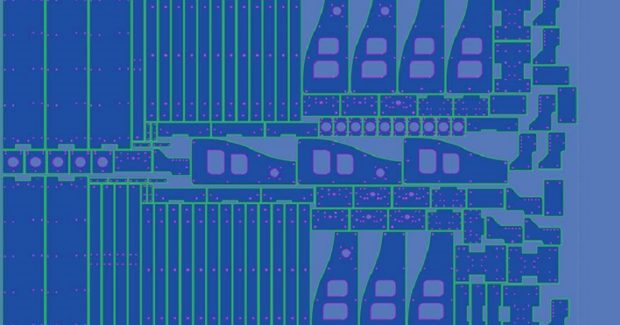

SigmaNEST X1.4 CAD/CAM nesting software from SigmaTEK optimizes part nesting with faster speed and processing; integrates with ERP; supports SolidWorks 2018 and special geometry-based clamps.

Posted: August 22, 2018

For mission critical work, fabricators use SigmaNEST X1.4 CAD/CAM nesting software from SigmaTEK Systems, LLC (Cincinnati, OH) so their machines can achieve peak performance through increased speed, improved functionality and higher overall quality. This software includes several ground-breaking enhancements to key modules:

- SimTrans Web. This transaction management application bridges the gap between SigmaNEST and most major ERP systems for an integrated experience.

- Load Manager. This production workload management tool is fully 64-bit compatible to increase speed and processing capabilities.

- Knowledge Base. A user-friendly platform for SigmaNEST programmers.

- SolidWorks integration. Support of SolidWorks 2018, filtering of SolidWorks parts and assemblies by folder on import.

- Advanced NC for Clamps. Support of geometry-based clamps for machines with specially-shaped clamps.

- HD SuperNEST. Support of Best Sheet options and the Continuous Nesting module by HD SuperNEST.

“This release covers improvements for every type of user and is one step closer to reaching complete automation, ” noted Jim Lindsey, a director and product manager at SigmaTEK, which also offers SigmaTUBE X1.1 software with features such as partial common line nesting, new supported shapes, IFC file import, a new help center and more. For users with the Advanced NC module, SigmaTUBE X1.1 supports partial common-line geometries that include both 4-axis and 5-axis toolpaths. Three new tube shapes are also supported: triangle shape, C-shape and D-shape tubes. Users can also import .ifc files from third-party structural modeling programs. The software features a new tangency tolerance configuration option that can be used to auto-generate toolpath parts with variable flange thickness. This allows users to generate toolpath for angle and channel parts that do not have uniform thickness.

An optional constant chuck tessellation configuration can be specified for straight profile cuts on round tubing. This allows a user to perform a 360 deg rotation using set angle rotations, instead of relying on the full tessellated toolpath, and decreases the number of lines output in the NC for these cuts. The SigmaTUBE Help Center is the hub for all SigmaTUBE information where users can view tutorials, help pages, videos, and more. Legacy content is updated and rewritten to follow the SigmaTUBE workflow, making it easier for users to find what thet are looking for.

SigmaTEK Systems, LLC, 1445 Kemper Meadow Drive, Cincinnati, OH 45240, 513-674-0005, www.sigmanest.com.