Down to the Wire

WireCrafters faced a dilemma: Manually welding their stock products had become too difficult to maintain during peak seasons. Hiring temporary welders was expensive. They needed smaller batch sizes and better inventory returns. What could they do?

Posted: August 23, 2018

Half a century of market leadership in woven and welded wire partition production hasn’t deterred the Diebold family from seeking lean initiatives or innovative technologies to better the operations for their privately owned, family-run company. Founded in 1967, WireCrafters LLC (Louisville, KY) started as a wire job shop dedicated to the development and manufacturing of a sole product that would benefit the safety, security and storage needs of the commercial and industrial marketplace. Through creative employee efforts, the Style 840 wire partition panel was designed that paved the way for future modular steel systems and related material handling equipment. Their state-of-the-art manufacturing facility serves to enhance innovation and meet unique demand for major suppliers, independent dealerships and large OEMs, including Yaskawa Motoman® (Miamisburg, OH) – because wire partitions are commonly used for machine guarding and robotic workcells where safety is a major concern.

Contrary to traditional partitions, WireCrafters systems are based on a building-block approach where panels stack one on top of the other between tubular posts to reach a desired height. This configuration gives users the ability to create long runs of partitions over 30 ft tall using stock panels made from domestically-produced raw materials. Delivering the exact fit, form and function agreed upon in a timely manner to meet specific customer needs is paramount to their success, so when the manual manufacturing of their 20 stock Style 840 partition panels became difficult to maintain during peak seasons, the shop decided to evaluate their production process. Their established MIG welding process for the one-foot increment panels – ranging from 1 ft to 10 ft wide, in heights of 4 ft and 5 ft – involved one to two skilled workers utilizing a fixture table to complete all manual welds for each angle frame and mesh. Hiring temporary welders to meet the seasonality of customer demand for these panels grew expensive and produced varying weld quality and lot sizes.

To create smaller batch sizes and gain better inventory returns more consistent with lean objectives, they searched for a cost-effective system to address production dilemmas. Much of their initial focus centered around the idea of creating a repeatable weld point, but increased costs and greater variability from upstream methods (rather than downstream processing) prompted them to focus on robotic automation. However, the process being considered included a lot of moving parts and needed specific vision technology to consistently determine optimal weld line location, and the technological advancements at that time were still years away from providing the ideal system. After nearly a decade of innovative testing and high-tech improvements, the shop seized the opportunity to partner with a trusted integrator and acquire a custom robotic workcell to assist with producing stock panels to optimize operations and meet customer demand.

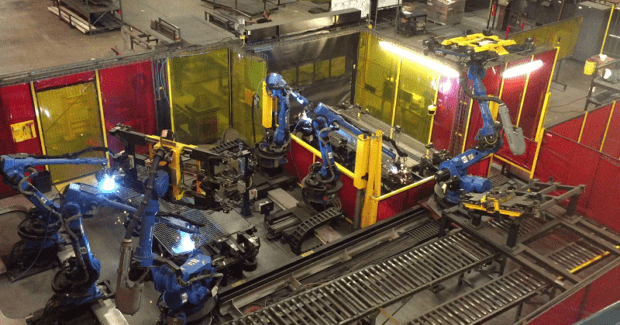

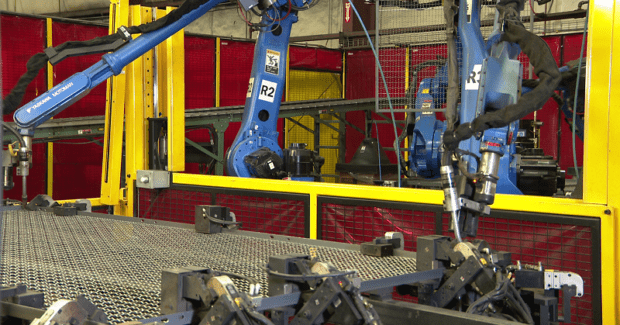

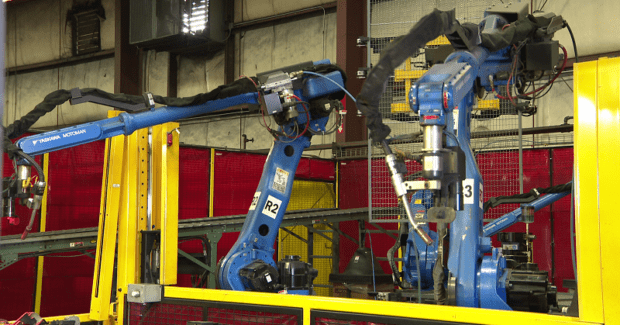

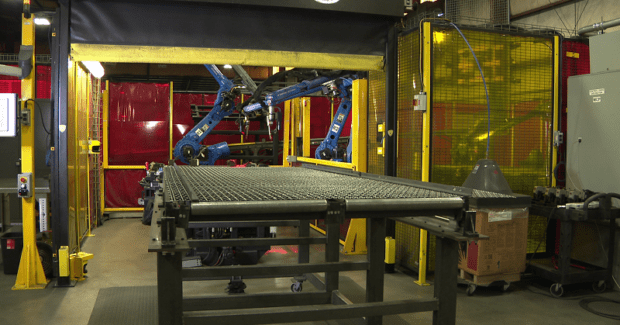

Their complex application needs prompted the integrator to do a thorough component search to achieve the optimal workcell design. The shop eventually implemented an automated panel welding system to robotically weld angle frame components and mesh to angle frames for the manufacturing of stock partition panels. This system features a total of six Yaskawa Motoman robots: four powerful MH50-20 long-reach robots equipped with a Miller Auto-Axcess™ 300 RMD power supply for welding and two MH50 high performance robots for material handling. To detect variance in the weld target location before the start of each weld, each MH50-20 uses a MotoSight™ 2D vision system with Pendant Vision application software and a Cognex In-Sight® Micro camera. This hardware and software system adds vision functionality to the robot to return critical X- and Y-axis information to the robot controller to manage the complex vision issues in this application.

Manufacturing stock partition panels with robotic automation has improved efficiencies and leveled production. The custom-designed automated panel welding system reduced the cycle time for the manufacturing of stock panels by half and eliminated seasonal production challenges, creating a consistent schedule to meet year-round demand. To assure the best possible return on their investment, WireCrafters sent a team of workers to a total of 23 classes at Yaskawa Academy, an accredited IACET provider and world-class robotics training facility located at the company headquarters in Miamisburg. The course instructions were not only relevant to the new welding system, but employees were also able to apply the knowledge gained toward other processes on the shop floor. Using this and thorough customer service backed by accurate and on-time information from technicians, WireCrafters smoothly navigated through the robot programming learning curve.

This system requires minimal manpower investment: two operators manage the workcell and subsequent part transfer for each ten-hour shift. The system operates 20 hours a day, four days a week to maintain regular production and Fridays are used to fulfill extra demand as needed. Any non-seasonal worker that is regularly assigned to manufacturing stock panels prior to robotic implementation is now put to tasks concerning custom partition orders to achieve overall company growth initiatives. A corporate strategy for future success has WireCrafters well on their way to exceeding ROI. Not only has robotic automation delivered transformative results, the custom configuration of this system provides them with the flexibility needed to adapt to market needs.

WireCrafters LLC, 6208 Strawberry Lane, Louisville, KY 40214, 502-363-6691, [email protected], www.wirecrafters.com.

Yaskawa America, Inc., Motoman Robotics Division, 100 Automation Way, Miamisburg, OH 45342, 937-847-6200, Fax: 937-847-6277, www.motoman.com.