Critical Thinking: How to Make Chip Removal More Efficient, Effective and Profitable

Not all conveying systems are suited for every scrap-handling application. By using the proper conveyor to quickly transfer scrap and coolant from the machine tool for separation and processing, high volume machine shops can increase part production with less downtime between jobs, create more value for their scrap, and improve revenue by recycling coolant.

Posted: August 16, 2018

Producing as many parts as possible in the shortest amount of time is the ultimate objective in most high speed, high volume machine shops. Output and profit drive the bottom line for machining giant blocks of metal down to 10 to 20 percent of their original weight and size. Once complete, this machining process creates another challenge – and an opportunity for great cost savings – related to the huge volume of metal chips, shavings, grindings and turnings it leaves behind. Allowing all of this scrap to pile up on the shop floor is neither reasonable nor safe for operating gantry mills and other machine tools. Using shovels to manually remove the scrap is equally impractical: health and safety concerns aside, it is nearly impossible for humans to keep up with the frequency and volume of material being generated. Instead, an automated conveying system is ideal for efficiently and expediently moving these large quantities of metal scrap out of the machines and their work zone to another area for processing, disposal or recycling.

Understanding how these machine shops operate is a critical prerequisite for purchasing a scrap metal handling system. These shops typically employ milling machines that are 30-50 ft long and 10-15 ft wide. Setting a 3,000 lb block of aluminum on one of these machines and reducing it to a single 300 lb part will generate 2,700 lb of aluminum shavings. Consider how much material will be left on the gantry tables when dozens or hundreds of orders are filled for the same part. To guarantee a quality product and surface finish, this material must be removed as quickly as possible to maintain a clean work area.

Heavy machining such as this typically requires the use of coolant, which can affect the composition of scrap metal. Proper coolant treatment and handling can also influence the type of conveying equipment that is suited for the task at hand. A critical part of scrap removal is spraying heavy-flow flood coolant on the tool during high-rate applications. This separates the scrap from the tool and helps control high temperatures, which speeds up cutting and extends the life of the equipment. Using less coolant is another option some shops have introduced by using a vacuum-type system to pull drier chips off the tool, but this practice runs counter to the goal of getting more profits and life expectancy out of the machines. Even though reduced coolant use can equate to less cost, it typically slows down the machining process and compromises production rates.

Valuable open floor space can quickly disappear given the size of these milling machines and the formidable tonnage of chips and turnings they produce. Adding flood coolant into the mix makes it essential that an automated conveying system be used to effectively manage the sheer volume of scrap and fluid and eliminate the manual risks of trying to shovel this material. Several conveyor options are available, each having advantages and disadvantages depending on the specific high rate application. Four main factors influence any conveying decision: the type of material, the chip profile, the type and amount of coolant used.

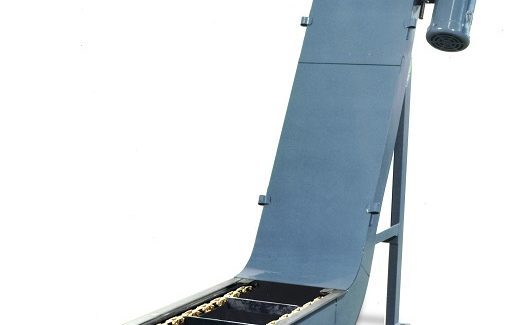

A steel belt conveyor is the simplest and one of the most versatile systems for material scrap handling. It can handle most wet or dry metal scrap – from bushy material to chips and turnings – in any quantity, and in a wide variety of conveyor channels. The industry standard is the hinged steel belt conveyor, but there are three more distinct categories of belts that can be applied according to the specific application, including:

- Beaded Pan – for high heat and heavy wear applications.

- Pivot Belt™ – for small, thin chips and sticky scrap.

- Bucket Belt – for conveying highly flowable material up a steep incline.

Steel belt conveyors move large volumes of material reliably, even in piles and high surges, but they aren’t the best system for managing high volumes of liquid flow. They also have a number of moving parts that deteriorate quickly and require maintenance when chips and fine particulate enter the mechanism.

The next option is a drag conveyor that can transport and elevate the most difficult, most abrasive, wet or dry materials in severe-duty conditions. These conveyors can be installed at floor level to more easily move material from the machine table to the conveyor. Options to address specific infeed and discharge points are also available and can be customized with coolant pumps for incorporation into chip and fluid filtration systems. Drag conveyors handle higher coolant volume than steel belt conveyors, have fewer moving parts, and deliver a more constant material flow in contrast to surge loading. They are not ideal for transferring cutoffs, bar ends, tooling pieces and other solid materials or parts through the conveyor. They are also not beneficial for handling longer, stringier drill chips or turnings that can twist up and bundle.

Trough-type conveyors transfer all types of metal chips, fines and turnings, wet or dry bushy wads, and tramp metal solids with time and energy-saving efficiency. Their liquid-tight trough design is ideal for high volume coolant flow applications, and their flush-with-the-floor placement allows both material and coolant to enter directly into the conveyor, curtailing manual interaction or slowdown of the process. The two types of trough-type conveyors are Harpoon® trough and Push-Bar™ reciprocating ram conveyors. The Harpoon trough conveyor has a ram assembly that hovers in the trough and reciprocates back and forth, collecting high volumes of turnings, chips, stringies and as much fluid as directed. They can even pass small chunks of solid material that wind up in the trough. While this conveyance method is a little slower than others, a Harpoon trough can deliver the same results as a faster moving conveyor because it can move a higher volume of material.

The Harpoon system may be preferable with large quantities of fine particulate because it scrapes along the bottom of the trough and will do a more thorough job of cleaning out the particulate. One of the issues that can develop as the ram assembly reciprocates is component deterioration through metal-on-metal contact with the bottom of the trough. The Push-Bar trough conveyor was developed specifically to address this issue. In this type of conveyor, the ram assembly is fixed to a bushing and rail system that lifts it off the bottom of the trough. This allows fluid and fine particulate to pass through the conveyor along the bottom of the trough, eliminating the threat of wear and tear. In the Push-Bar system, some amount of leftover material is always present because the ram assembly is positioned slightly above the bottom of the trough.

Automating the chip removal process is critical for increasing efficiency, quality and profit in machine shops with high Q rates. By applying conveyors to quickly transfer scrap and coolant from machine tools to a central collection area for separation and processing, they can experience increased part production with less downtime between jobs, create more value for their scrap, and improve revenue by recycling coolant. Not all conveying systems are suited for every scrap-handling application, but taking the time to understand and assess how each option applies to your operation – ideally with the input of a trusted, experienced supplier – you can select the best system for achieving the greatest return on your investment.