Ultra-Short Pulse Laser for Medical Device Manufacturing and More

Ideal for marking reusable surgical instruments and endoscopes, the TruMicro 2000 picosecond laser from TRUMPF is suited for applications ranging from high quality metal engraving to cutting extremely thin films, to corrosion-free marking of medical instruments and chrome-plated plastics.

Posted: July 17, 2018

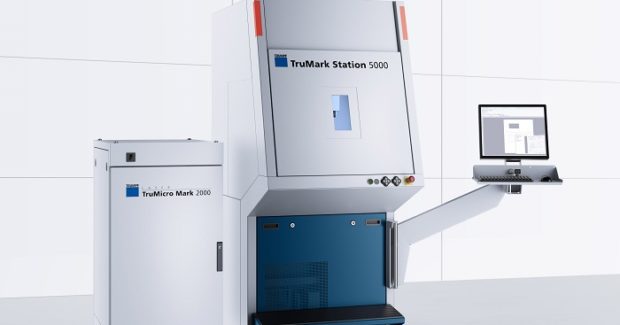

The TruMicro 2000 picosecond laser from TRUMPF Inc. (Farmington, CT) is ideal for a variety of applications ranging from high quality metal engraving to cutting extremely thin films, as well as for corrosion-free marking of medical instruments and chrome-plated plastics. With extremely short laser pulses ranging from 0.4 ps to 20 ps and a peak power of 20 microjoules, the TruMicro 2000 is capable of cold processing: as soon as the material being processed by the laser pulse begins to register a thermal process, it’s already over. The result is that any undesirable thermal effects, such as micro-fissures and residual melt that would otherwise arise during material processing, are nowhere to be found due to the very small heat-affected zone. This makes extremely precise applications – such as smooth surfaces and deep black markings – possible on a variety of materials.

This laser is especially attractive for applications in the area of medical technology, particularly for reusable tools such as surgical instruments and endoscopes that require uniform labels in the U.S. market so they can be easily traced. The TruMicro 2000 is capable of marking even highly reflective materials. These markings remain corrosion-free despite daily cleaning and sterilization, and exhibit a strong visual contrast. The high peak pulse power of the picoseconds laser creates a nanostructure on the surface of the workpiece. The rough surface produces a sort of light trap that reduces the diffuse scattering of the light and evokes a permanently black mark. The special quality of this process is that the steel’s chromium oxide layer remains intact, which prevents corrosion from forming. Up to this point, results like this have been unachievable with traditional marking lasers that operate in the nanosecond range. The advantages offered by the TruMicro 2000 are also seen with chrome-plated plastics used in common consumer products, such as showerheads and automobile interiors.

This system is capable of much more than just marking. It can be used for a multitude of microprocessing applications, including more in medical technology. Picosecond lasers are enjoying an increasingly important role in the production of stents used to keep blood vessels open. An essential quality of stents is smooth surfaces free of any burrs. These help prevent blood platelets from accumulating. Today, medical professionals are moving away from stents made from steel in favor of those produced from nitinol, an alloy which causes less fatigue and is better received by patients. But nitinol is extremely heat sensitive and nearly economically unfeasible to produce using standard processes. This is where picosecond lasers come in. Due to cold processing, the TruMicro 2000 makes it possible to prepare the surface of the stent without damaging the material.

The TruMicro 2000 can service a broad spectrum of microprocessing applications ranging from marking, engraving and structuring to cutting and ablation. A host of advanced features make this level of flexibility possible. The Pulse on Demand feature, for example, enables the operator to apply the laser pulse to any desired location with micrometer accuracy. This allows extremely precise work when processing a variety of different materials. The TruMicro 2000 also features a double power regulation which makes it possible to precisely set the power from pulse to pulse.

TRUMPF Inc., 111 Hyde Road, Farmington Industrial Park, Farmington, CT 06032, 860-255-6000, Fax: 860-255-6424, www.us.trumpf.com.