Powerful CAM Software Increases Machining Productivity and Reduces Overall Production Costs

Mastercam 2019 from CNC Software features a new series of automated 2D through 5-axis toolpath improvements, multi-axis milling automation, CAD and model preparation improvements, expanded 3D tooling, Accelerated Finishing and turning and Mill-Turn enhancements.

Posted: July 10, 2018

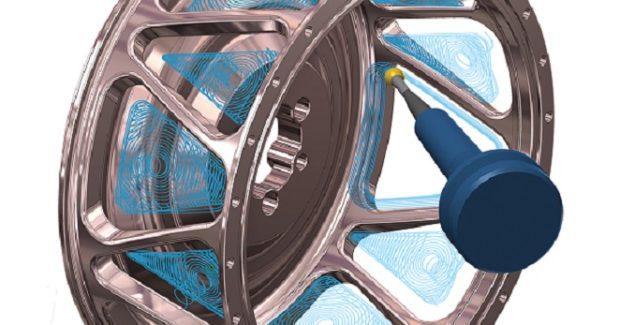

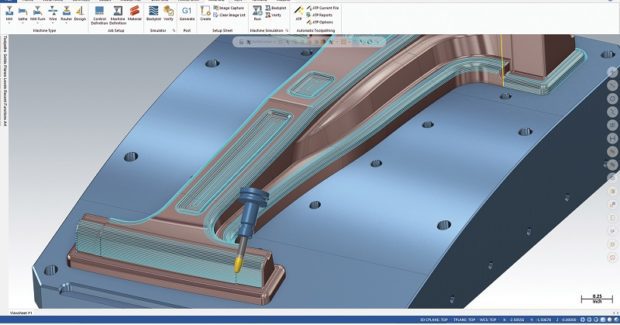

In Booth E-133340, CNC Software, Inc. (Tolland, CT) will showcase their powerful Mastercam® 2019 machining software for increased machining productivity that reduces overall production costs with a new series of automated 2D through 5-axis toolpath improvements, multi-axis milling automation features, CAD and model preparation improvements, expanded 3D tooling, Accelerated Finishing™, and powerful turning and Mill-Turn enhancements. Re-engineered chamfering and holemaking strategies, plus new multi-axis deburring increase levels of time-saving automation and simplicity. New milling toolpath strategies, like the high speed Equal Scallop toolpath, offer both machining performance and surface finish improvements. Additional support for the Sandvik Coromant PrimeTurning™ method, enhanced grooving, bar feed, and other features for turning and mill-turn applications, plus new lathe and Swiss-style machine support are also included.

Mastercam 2019 increases efficiency, reduces job setup time and the preparation needed for part machining and programming with enhanced CAD functionality and 3D model import support, improved part preparation and fixture setup tools, additional PowerSurface capabilities and expanded support for Model-Based Definition (MBD). The expanded digital tool library capability delivers accurate 3D tool assembly models, provides access to the latest cutting tool technology and updates for Sandvik Coromant CoroPlus and MachiningCloud platforms. The software also expands Accelerated Finishing with support for taper and lens style tools aimed at 75 percent cycle time improvement for finishing operations with superior surface finish quality. With improvements to toolpath and machine simulation, toolpath graphics, and other verification and analysis tools, greater programming assurance is provided for better, more informed decisions before a job is run. These improvements include support for block drilling multiple holes simultaneously and better axis control in simulation, allowing you to easily check machine limits or collision checking.

Mastercam 2019 also improves job documentation and management while helping to address quality and certification initiatives. New toolpath visualization capabilities and section view tools, improvements to view and setup sheets, and a wide array of system level enhancements improve efficiency in managing job workflow, as well as providing better tools for process documentation.

CNC Software, Inc., 671 Old Post Road, Tolland, CT 06084, 860-875-5006, www.mastercam.com.