Multi-Sensor Unit for Drawbar Inspection

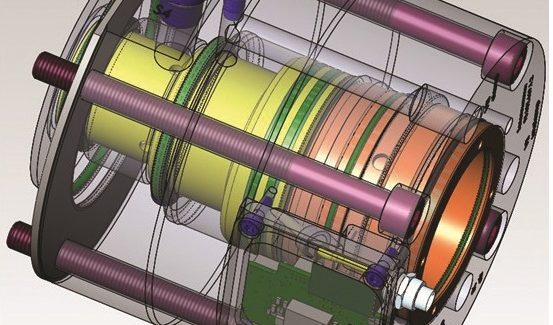

The MSU sensor system from Advanced Machine & Engineering combines a distance measurement system, a piston position monitor, and optional leakage detection into one compact, built-in multi-sensor and electronic evaluation system in the unclamping unit of a drawbar.

Posted: July 18, 2018

In Booth E-121117, the multi-sensor unit (MSU) sensor system from Advanced Machine & Engineering Co. (AME; Rockford, IL) is a built-in, multi-sensor and electronic evaluation system in the unclamping unit of a drawbar. It combines a distance measurement system, a piston position monitor, and optional leakage detection into one compact unit. The MSU provides preemptive maintenance that detects drawbar disruptions during the machining process, including:

- Chatter that leads to changes in the cutting performance and tool life.

- Fretting that results in a coppery discoloration and degradation on the tool holder’s taper.

- Degradation of the surface finish.

- Repeatability of machining processes.

An optional leakage sensor can also be added to the MSU sensor system to monitor internal or external leakage. External leakage monitoring detects the presence of coolant or oil in the leakage tube. Internal leakage monitoring detects coolant in the area of the sealing bushings and flooding of the bearings inside the rotary union.

Advanced Machine & Engineering Co., 2500 Latham Street, Rockford, IL 61103, 815-962-6076, Fax: 815-962-6483, www.ame.com.