Metal Chip Processing, Fluid Filtration, Industrial Water and Wastewater Treatment Systems

For full-scale metal turnings and chip processing capabilities, PRAB offers the Dualpak Briquetter with enhanced 3D digital animation, the Diagonal-Shaft Wringer, the Guardian Coolant Recycling System, the Paper Bed Filter and EVALED Vacuum Evaporation and Distillation for industrial water and wastewater treatment.

Posted: July 18, 2018

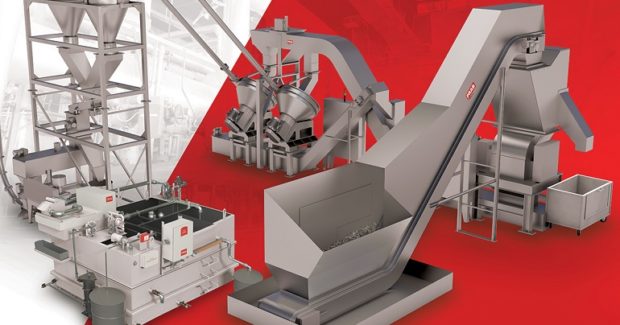

In Booth E-121124, PRAB, Inc. (Kalamazoo, MI) will feature full-scale metal turnings and chip processing capabilities and will demonstrate their Dualpak™ Briquetter using enhanced 3D digital animation. Visitors will see inside the system as it works in series to compress metal chips, loose turnings and swarf into near solid, dry briquettes to send to the recycler or feed to furnace. Also featured will be their Diagonal-Shaft Wringer, Guardian™ Coolant Recycling System, Paper Bed Filter and EVALED™ Vacuum Evaporation and Distillation for industrial water and wastewater treatment. “Our job as a provider of scrap and fluid processing equipment and maintenance support to the metalworking community is more vital than ever,” noted Mike Hook, the national sales manager for PRAB. “The metalworking industry is taking on shifts in the needs of the automotive and aerospace OEMs that are dealing with new steel and aluminum formulas, more-difficult-to machine alloys such as titanium, and the ability to handle a greater mix of metals and alloys. These factors change the machining dynamics, make-up and volume of solid and liquid waste. Shops rely on us to assess their changing operating conditions and offer the most comprehensive equipment to quickly and automatically handle scrap for recycling and metalworking fluid reuse.”

PRAB engineers and manufactures equipment based upon the exact needs and specifications of the application so that a shop or OEM is assured the equipment will work in the application for which it was designed and deliver long-term, reliable service. “The material and flow dynamics in shredding, crushing, separating, and briquetting metals are not as straight forward as one might think. You are dealing with variations of nested turnings, a range of size and density in tramp metals, and differences in the type and volume of fluids. Providing equipment to handle these variations cannot be a cookie-cutter approach,” added Hook. Their heavy duty wringers/centrifuges use more than 600 G of force to reclaim up to 98 percent of the valuable coolant and cutting oils from aluminum, brass, cast iron, steel, stainless steel and other metal chips. This process significantly reduces haul-away cost and increases the value of dry chips.

The Guardian Coolant Recycling System is a centralized, economical solution to the high costs associated with maintaining water-based coolants and washwater in the metalworking industry. This system recycles used coolants, reducing waste fluids by 50 percent to 90 percent, and eliminates concerns about wastewater haul-away liabilities. Everything needed for centralized coolant recycling is included with the Guardian. Each turnkey system is designed for easy installation, quick start-up, and simple, efficient operation. A full line of Paper Bed Filters is a low-profile, cost-effective system for solids filtration that can significantly lower operational costs. These filters provide long-term answers for solids filtration, with or without magnetic separation, and are perfect for grinding applications. Filtered fluid can be reused or recycled, lowering operational costs.

The EVALED Vacuum Evaporation and Distillation system is for treating wastewater in a wide range of industrial applications, such as exhausted oil emulsions, tumbling baths, parts rinsing waters, ion exchange regeneration, pretreatment baths, pickling baths, rinsing baths (cyanide, copper, zinc, nickel, cobalt, cadmium, chromium) and more. Every EVALED evaporator operates as a closed-loop system under vacuum. Atmospheric evaporators lose valuable energy through air emissions and may require an air permit or waiver for compliant operation. An EVALED evaporator has an efficient design with one inlet and two discharge streams: concentrate and distillate. No air emissions ever. A water analysis is performed to determine the exact equipment requirements to meet reuse or approved dumping requirements.

“We are faced daily with water scarcity globally and certainly within metalworking operations it is important for companies to reuse their process water to the extent possible,” stated Tim Hanna, the vice president of business development for PRAB Water & Wastewater Division. “EVALED Vacuum Distillation Evaporators provide energy efficient (low carbon footprint) and Zero Liquid Discharge (ZLD) models for treating process and wastewaters.”

PRAB, Inc., 5801 E N Avenue, Kalamazoo, MI 49048, 269-382-8200, Fax: 269-382-7770, www.prab.com.