Industry 4.0 CAM Software Reduces Cycle Times, Improves Milling Surface Finishes

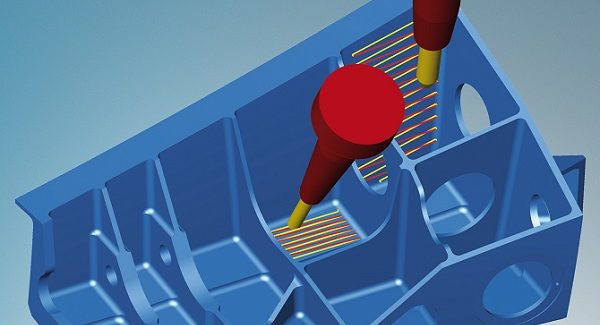

Integrated hyperMILL MAXX Machining finishing software from OPEN MIND uses conical barrel cutter technology to reduce machining cycle times by over 90 percent on planar, ruled and curved surfaces in complex, 5-axis components.

Posted: July 10, 2018

In Booth E-133351, OPEN MIND Technologies USA, Inc. (Needham, MA), will showcase the advanced capabilities of hyperMILL® 2019.1 CAM software, including greater blending capabilities, 3D-optimized roughing and finishing, global fitting, rotational abilities for CAD electrode applications, and the debut of virtual machining simulation. Developed with Industry 4.0 in mind, VIRTUAL Machining enables constant real-time bi-directional communication between the machine tool controller and a remote VIRTUAL Machining simulation, significantly improving manufacturing workflow. For reduced programming time and improved milling, two new functions for 3D Z-level Shape Finishing include an “Automatic Face Extension” capability that can be used during programming to extend the selected milling surfaces, eliminating the need to modify the milling faces in the CAD system beforehand. Barrel cutters (in addition to general, tangential and conical barrel cutters) can also now be used for 3D Z-level Shape Finishing. 3D Optimized Roughing has also been enhanced, to ensure that multiple allowances are taken into account when free tool geometries are used.

This software enables revolutionary 5-axis strategies for fast, easy-to-use programming, resulting in reduced cycle times and high-quality surface finishes. The integrated MAXX Machining finishing module, a performance package of this CAM software suite, is the programming source enabling the use of conical barrel cutter technology to reduce machining cycle times by over 90 percent. It is ideal for planar, ruled and curved surfaces often found in complex 5-axis components. MAXX Machining offers three powerful modules for finishing, roughing and drilling. Attendees can learn about some other new features planned for this hyperMILL 2019.1 release, including high precision machining using ball end mills and equidistant machining with multiple island capabilities to create better surface finishes. Visitors are also invited speak with the application experts to learn about the new, highly efficient rollFEED® turning strategy.

A basketball hoop that was successfully machined using 5-axis programming from hyperMILL will be on display in the booth so that visitors can apply their hoop shooting skills. Starting with a 180 lb block of aluminum and using a 12.6 in (320 mm) length cutting tool, the finished basketball hoop was milled to 1b 4 oz, a 99.3 percent material reduction. The hoop has an intricate design that was machined to the finest levels of detail.

OPEN MIND Technologies USA, Inc., 1492 Highland Avenue, Unit 3, Needham MA 02492, 339-225-4557, Fax: 270-912-5822, [email protected], www.openmind-tech.com.