High Volume Gundrilling of Scroll Compressor Drive Shafts

The DeHoff 518 Cell from Kays Engineering uses nine gundrilling spindles to drill opposing holes in balanced throughput: three on a single machine base for the larger diameter shorter hole, and six others on two separate machine bases for the smaller diameter deeper hole.

Posted: July 21, 2018

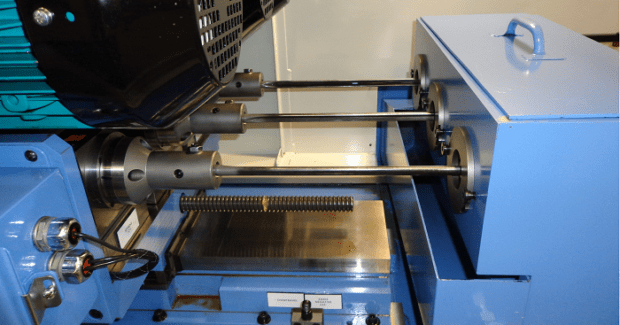

In Booth S-338376, the DeHoff 518 Cell from Kays Engineering, Inc. (Marshall, MO) is a gundrilling machine for high volume production of scroll compressor drive shafts that require a different diameter hole to be drilled in each end for lubrication of the scroll bearing. The 518 Cell is comprised of nine gundrilling spindles used to drill the opposing holes. The larger diameter, shorter hole is produced first using three gundrilling spindles on a single machine base. The smaller diameter, deeper hole is produced next using six gundrilling spindles (two separate machine bases with 3 spindles each). More spindles are dedicated to the deeper hole because of its longer cycle time, which results in a balanced throughput for each gundrilling operation. The 518 Cell has a 0.5 in (12.7 mm) gundrilling capacity and an 18 in (457 mm) slide travel. This machine features a cast iron drill head base with hardened and ground steel box ways, plus hand-scraped and fitted saddle, gibs, and straps (versus linear guide ways and milled surfaces) for superior vibration damping, extended tool life, and improved accuracy and surface finish. These DeHoff gundrilling machines are built-to-order by Kays Engineering in their Marshall facility.

Kays Engineering, Inc., 900 Industrial Drive, Marshall, MO 65340, 660-886-9929, Fax: 660-886-2249, www.kays-dehoff.com.