High Performance Taps, Drills and End Mills

GARANT MasterTap from Hoffmann guarantees reliable thread machining in a wide range of materials, including steel, stainless steel, aluminum, brass and cast iron.

Posted: July 27, 2018

In Booth W-432568, Hoffmann Group USA (Knoxville, TN) displays their GARANT MasterTap universal high performance tap for thread machining a wide range of materials. It is the result of a fundamentally new development concept for the design of universal taps. The tool achieves outstanding process reliability with high efficiency in a much wider range of materials than previous universal taps, including steel, stainless steel, aluminum, brass and cast iron. The key to its unique versatility is its ability to remove chips perfectly. This special feature is due to a new cutting-edge geometry as well as optimized flutes that facilitate reliable removal of the chips. Winding chips and loose swarf are consistently avoided. When reversing in blind hole machining, the GARANT MasterTap ensures an extremely reliable process as the chips are sheared off in a targeted manner via the specially designed tooth back and the chip roots are smoothed for various materials such as steel, stainless steel, aluminum, brass and cast iron.

The strengths of the tool shine in particular when machining high strength steel materials, thanks to its deliberately rounded cutting edges. The rounding also ensures a defined and continuous wear behavior without breakouts and thus for a longer service life. To achieve particularly high performance and longevity, a high quality HSS-E-PM cutting material and an AlTiX high performance coating were chosen for the production of the new GARANT MasterTap. The special ultra-smooth AlTiX coating protects against premature wear and allows high cutting speeds, even in Al-wrought alloys, because the low friction values prevent material sticking and thread corrosion. Thanks to its special guide thread, the tool achieves precise results without axial slicing even in ductile copper alloys.

Also on display will be the GARANT MasterSteel FEED and SPEED solid carbide drills. Featuring three cutters, the new FEED generates up to 50 percent more feed per rotation and offers a particularly long tool life, whereas the new SPEED comes with two cutters and offers extremely high cutting speeds. As such, Hoffmann can offer the perfect tool for any application. The FEED and SPEED have been optimized to suit a range of production environments. The 3-cutter FEED reaches its maximum performance on machining centers with a high spindle output and high torque, whereas the SPEED has been designed for tooling machinery with a low spindle output but a high speed, as well as for thin-walled components. This means users can get the exact tool they require to suit the design of the drive unit, fixing, component and application.

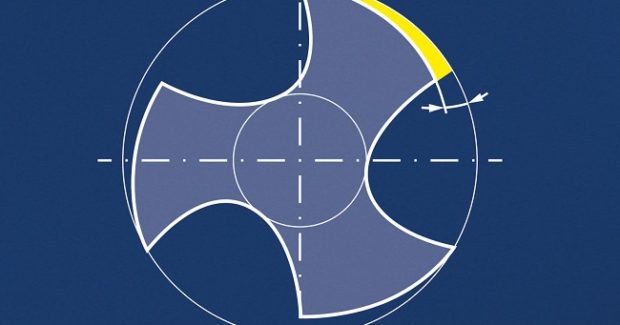

The GARANT MasterSteel FEED solid carbide drill uses three cutters with a special form, robust cutting edges and a large clearance in the center. The patent-pending point geometry reduces the cutting pressure and its 145 deg point angle ensures an optimized chip flow and controlled chip breaking. In contrast to conventional 3-cutter tools, the FEED is also suitable for machining long-chipping materials, despite the comparatively small flutes. The tool boasts outstanding self-centering because the self-centering forces act on three cutters instead of just two. This means spot drilling can easily be carried out, even on critical and uneven surfaces. In order to ensure uniform, controlled wear and a long tool life, the flexural strength and toughness of the solid carbide substrate used has been improved. A multi-layer PVD coating has also been applied. The FEED is available for diameters of 4 mm to 20 mm.

The GARANT MasterSteel SPEED solid carbide drill has been designed for extreme cutting speeds and extremely high process temperatures. Thanks to a newly developed solid carbide substrate made from ultra-micro-grain together with a newly developed coating, the tool offers impressive durability even under extreme conditions. Due to its low thermal conductivity, the coating acts like a heat shield in order to prevent the carbide substrate from weakening. It remains extremely hard, even under very high temperatures, in contrast to other coatings which are weakened significantly. As a result, the SPEED can offer the longest tool life. Its slim chisel edge optimizes the self-centering of the drill as the material is cut to almost the very center rather than being merely displaced as is often the case. The guide chamfers have been pulled forwards to create optimal cylindrical bores. As a result, the second guide chamfer assists the drill at an early stage. The special major cutting edge reduces the cutting forces and guarantees exceptional drilling, even at high cutting speeds, meaning the SPEED can offer an unparalleled metal removal rate together with a long service life. The SPEED is available for the range from 2 mm to 20 mm.

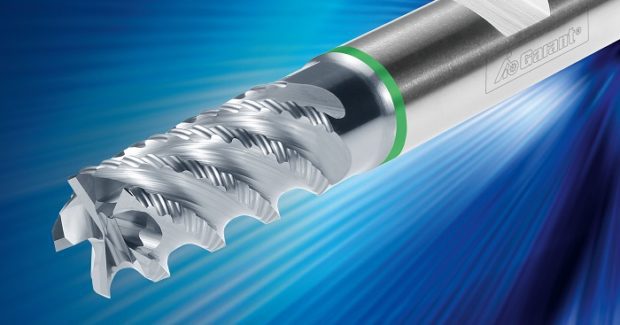

Also on display will be the GARANT MasterSteel SlotMachine solid carbide roughing end mill that achieves high feed rates when slot milling from solid steel. The innovative knuckle form profile produces extremely compact swarf. This is how Hoffmann was able to construct the milling cutter with five cutting edges. As a result, at a constant feed rate per tooth the new five-edge end mill achieves 25 percent higher process efficiency than a classic four-edge end mill. With the innovative knuckle form profile, the cutting pressure is lower and higher feed rates can be obtained with a constant load. Due to the compact chips and the lower cutting forces, this high performance end mill is particularly suitable both for milling deep slots and also for machining delicate components. Based on its unusual geometry, the SlotMachine produces chips that are very short, fine and particularly tightly rolled. These are easily cleared by the flat chip-breaker recesses. The directional chip discharge increases the process reliability, the extremely sturdy core diameter the tool stability.

The GARANT MasterSteel SlotMachine permits plunge angles up to ten degrees. The cutting edge design includes honing to minimize the risk of break-aways. The ultra-fine grain substrate greatly increases the resistance to breakage, while the enhanced coating also optimizes the wear characteristics and reduces the rate of heat input. The unequal spacing ensures a smooth cutting action. The SlotMachine achieves a feed rate per tooth up to 0.1 mm at cutting depths up to twice the tool diameter (2xD). It is available with cutter diameters from 4 mm to 20 mm.

Hoffmann Group USA, 202 North Seven Oaks Drive, Knoxville, TN 37922, 844-448-7725, www.hoffmann-group.com.