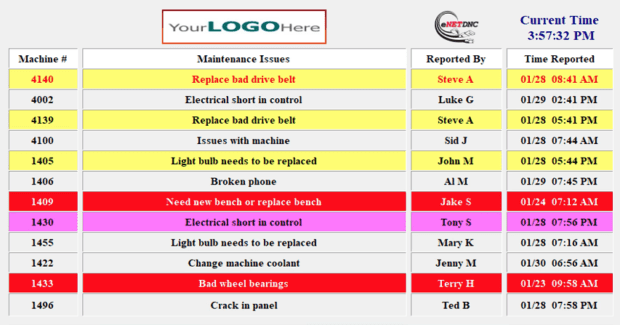

Full Real-Time Visibility of all Facility and Machine Maintenance Needs

Using eNETMD real-time Maintenance Dashboards from eNETDNC, a shop can schedule or prioritize today’s maintenance needs or even weekly, monthly and yearly preventative maintenance projects. It also offers an email server with automated notifications to improve communication within the maintenance department.

Posted: July 7, 2018

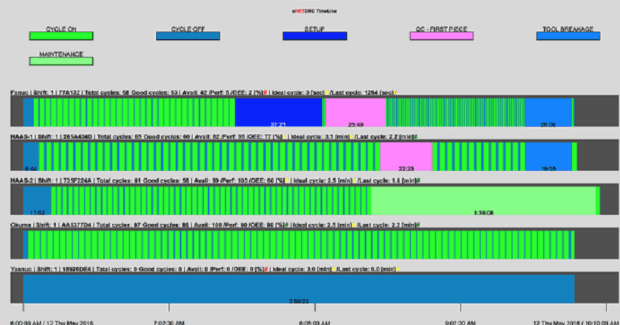

In Booth E-133316, eNETDNC (Greenfield, WI) will showcase their latest DNC and Machine Monitoring updates, including new Monitoring Reports and mobile web-based Monitoring Dashboards, and introduce eNETMD, a powerful yet easy-to-use Maintenance Dashboard that will simplify a shop’s maintenance scheduling and reporting. This customizable software is hosted on-site with a stream-lined design that will not stress the local network. This real-time Maintenance Dashboard allows for full visibility of all facility and machine maintenance needs throughout the whole organization. It is designed hand-in-hand with eNETDNC users to provide the most important CMMS tools without the clutter of unnecessary extras found in legacy CMMS systems. A shop can schedule or prioritize today’s maintenance needs or even weekly, monthly and yearly preventative maintenance projects. eNETMD also offers an email server with automated notifications to improve communication within the maintenance department.

eNETDNC is the building block that works with any control, machine type, comm port type or version of Windows. This same configuration carries over to the Machine Monitoring system by utilizing Data I/O boards to automatically capture machine data and provide utilization data from every machine tool, whether CNC or manual. The Monitoring Boards also give shops the powerful ability to force operators to report machine down-time reasons through simple barcode scans. The eTerminal even allows for additional job and operator-related data collection at each machine, rather than have operators waste valuable chip-cutting time standing in lines at ERP kiosks.

eNETDNC, 4702 South 47th Street, Greenfield, WI 53220, 414-817-7070, Fax: 414-817-8386, www.enetdnc.com.