Engineering Software Streamlines the Entire Manufacturing Workflow

3DXpert 14, GibbsCAM 13 and Cimatron 14 from 3D Systems cover digitization, design and simulation through to manufacturing, inspection and management.

Posted: July 7, 2018

In Booth E-133310, 3D Systems (Rock Hill, SC) will feature their comprehensive engineering software portfolio of reverse engineering, design for additive manufacturing, CAD/CAM and tooling design, and 3D inspection that enables streamlined prototyping and production workflows in both traditional and additive manufacturing to deliver a new level of productivity, efficiency, and faster time to market. These systems cover and streamline the entire manufacturing workflow, from digitization to design and simulate, through to manufacture, inspect and manage. Three new software releases will be showcased: 3DXpert™ 14, GibbsCAM® 13 and Cimatron® 14.

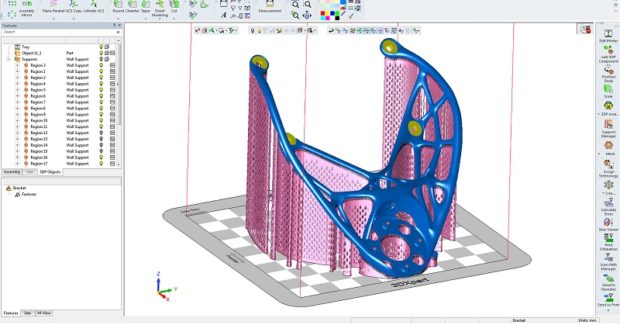

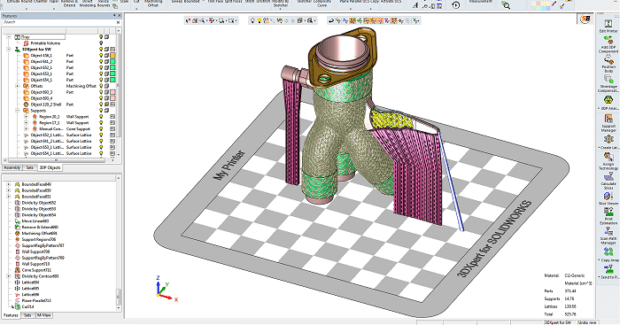

3DXpert 14 is the newest version of their unique all-in-one Design for Additive Manufacturing (DfAM) software, with enhancements focused on facilitating the entire production cycle to support manufacturers as they transition from using additive manufacturing for prototyping to full production applications. This software helps print managers optimize total cost of operation (TCO) through reduced print times, material consumption and post-processing labor requirements:

- Intelligent multi-head control and auto-balancing set a new standard for performance. Through enhanced control, including laser synchronization, gas flow and correct hatching order, 3DXpert 14 shortens the print time for high quality large parts while helping maintain material integrity.

- Advanced built-in templates and automation tools shorten the print preparation time from design to the first batch of repeatable quality prints, including:

- More options for orientation analysis using stress approximation.

- New support structure options.

- New lattice structure options and ready-made templates for generating lattices.

- Enhanced access to Build Simulation, including free versions for education as well as a new standard and professional version.

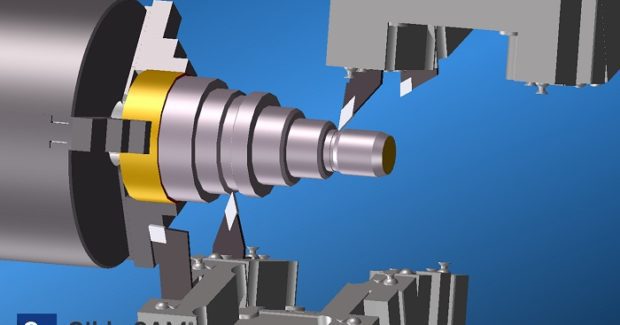

GibbsCAM 13 includes key enhancements throughout the product that further streamline the programming of CNC machining centers. Building from the recent interface improvements, this new release continues to increase functionality while maintaining the intuitive workflow that has made this CAM software a cornerstone in the programming of advanced machining centers. New features include:

- Advancements in turning capabilities include elliptical and eccentric turning. GibbsCAM now allows programming elliptical shapes and non-centerline turning inside the CAM package, eliminating the need for time-consuming calculations and programming on the machine controller.

- Interpolation turning gives turning capability to any machining center with an orientable spindle, such as 4-axis mills, MTM machines and boring machines, greatly expanding the capabilities of these powerful machine tools.

- Linear and rotary broaching programming has been added. Traditionally, broaching has been a hand-programmed or manual process. This release allows the programming of broaching routines, eliminating manual coding or extra setup time.

- Interface enhancements to this release build on those found in GibbsCAM 12 to create a faster, more fluid workflow when programming CNC machines. The ability to stack or group operations, along with a built in G-code editor, provides intuitive programming information in a single location.

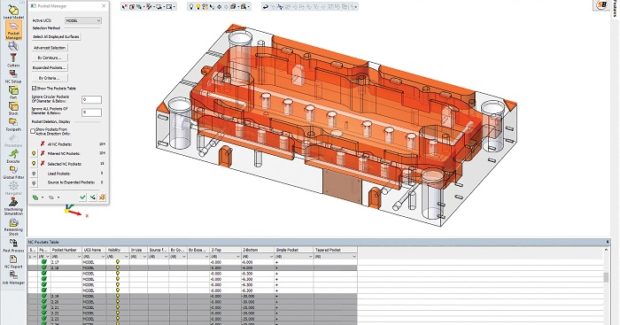

Cimatron 14 addresses the entire toolmaking process, from tool design to NC programming, to help shops improve their productivity and maintain a competitive advantage. NC programmers will benefit from faster and easier programming with the new feature-based machining, as well as faster machining time and better surface quality. Die makers can now run a simulation to calculate accurate trim lines and accurate springback effects in order to reduce or eliminate the number of tryouts by using the new integrated offering with ProgSim (from Autoform) Simulation. And mold makers will be introduced to new features that enable faster, easier mold design.

3D Systems, 333 Three D Systems Circle, Rock Hill, SC 29730, 803-326-3944, www.3dsystems.com.