Effective Vacuum Cleaning of Metal Debris and Recovery of Metal AM Powders

Vac-U-Max provides advanced systems for vacuuming the inside of the machine tool and large parts being machined, and recovery and reuse of metal powders used in additive manufacturing.

Posted: July 18, 2018

In Booth E-121035, engineered central vacuum cleaning systems from Vac-U-Max (Belleville, NJ) are designed with a high powered vacuum pump and unique Tube Hopper that collects and deposits chips onto existing below-floor mechanical chip conveyors. This vacuum cleaning system is used to manually clean the inside of the machine tool as well as large parts being machined that have a lot of nooks and crannies for chips and coolant to build up inside. The Tube Hopper discharges the collected chips onto a mechanical chip conveyor that runs beneath the floor level. This system is ideal for applications requiring the cleaning of all types of metal debris, including cast iron, steel, aluminum and composite chips, wet or dry, and other abrasive materials with coolant. The unit offers mildew-resistant filters that provide clog-free collection of all chips that fit through the hose, reducing cleaning times and increasing uptime for expensive machine tools.

Also on display will be the 55MW, a complete system for cleaning 100 percent liquids or liquids with solid particles, such as metal chips or shavings, enabling the operator to separate coolant from chips at rates of one gps to two gps (60 gpm to 120 gpm). Operators can quickly empty machine tool sumps, machining beds, oil/water separators, parts washers, rinse tanks and clean up liquid spills, vacuuming both coolant and chips directly into the collection container. Solid particles are separated from collected liquid with a Chip Basket and Liner, with coolant flowing through the basket directly into the collection container. Once finished vacuuming, unit can be switched from vacuuming to pumping out. The model 55MW allows the user to pump out the coolant or other liquid directly back into the machine tool or directly into a drum for disposal. The separation of coolant and chips in one step enables less down time and improves the handling of scrap. Additionally, recycling coolant keeps costs down and productivity up by extending coolant life, and machine tool filtration system life with the removal of chips and swarf.

The 55MW system offers the following features and benefits:

- Heavy Duty Construction: Rugged, fully welded dolly with large-diameter wheels for rough machine shop floors, powder coat finish with excellent chemical resistance.Easy Maneuvering: Dual swivel casters and compact size – only 26 in wide – gets close to the machine tools and sumps to keep vacuum hoses as short as possible.

- Fast working: Clean Up at 60 gpm to 120 gpm. Pump-out at up to 14 gpm.

- Versatility: 100 percent solids or 100 percent liquids, or any combination.

- No Moving Parts: Compressed air-powered vacuums work forever without any moving parts. Available as a pump-out cart for customers who already own a 55 gal air-powered drum-top vacuum.

- Clean Operation: Smoothbore hoses prevent accumulation of liquids and chips. Slotted holes in the cart base to prevent pooling of fluids . . . dispensing nozzle on the pump-out hose puts you in control of where and when the fluid comes out.

- Plug-and-Play: Includes an air-operated industrial vacuum cleaner and chip basket, collecting and separating liquids from solids in minutes.

- Industrial Design: Not available in home improvement stores. Powered by cool-running convenient compressed air, no motors to burn out. All-steel construction.

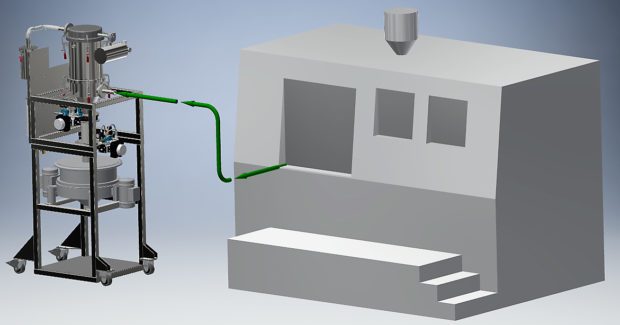

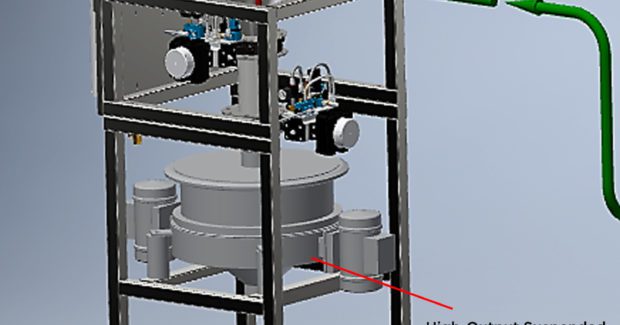

Also on display will be a new Metal Powder Recovery System (AM-MPRS) for additive manufacturing applications that now offers conveying, screening, recovering and reuse of metal powders including Inconel, stainless steel, Haynes 282, and cobalt chrome. The AM-MPRS increases productivity of additive manufacturing machines by extracting metal powders from the printing bed via vacuum, and then sieving the metal powder for future use – cutting metal powder recovery time by 85 percent. This system is designed for ease-of-use, conveying metal powders in a closed system, eliminating operator exposure to metal dusts, and maximizing plant and personnel safety. The AM-MPRS utilizes vacuum with system extracting the metal powder, conveying it to a vacuum receiver and then discharging the metal powder into a sieve. The sieve discharges metal powder into a pail, drum or IBC, in a contained and inert environment. The system is NFPA 484-compliant for handling metal powders and reduces the risk of cross-contamination. It allows full metal powder recovery and quick dismantle without tools. Ergonomic low-profile design and mobile frame allow easy rolling with lockable casters.

AM-MPRS includes pick-up hand tool and static-conductive hose with smooth bore. Hoses for non-aerospace applications are available in PVC construction, both FDA and USDA approved. Aerospace applications are offered with flexible stainless-steel hose with smooth bore construction. The system offers inert gas-purge fittings and optional gas-purge manifold supplied at customers request. Additional features include HEPA Filter canister with filter, high output suspended vibratory sieving machine with US230 mesh, ultrasonic de-blinding kit, and a Vacuum Receiver.

The 316L Stainless-Steel Vacuum Receiver package offers 36 sq ft of filter area and counter-weighted discharge valve. Vacuum Generator includes a Single Venturi Power Unit. Compressed air is driven by a vacuum generator with a ½ in NPT high pressure air connection. The system requires 35 CFM at 60 psi for operation, with variable orifice assembly for adjustment of vacuum levels. A NEMA 4, UL-Certified Control Panel offers Micro-PLC for vacuum conveying functions, starter for sieve, grounding and bonding monitor, and face-mount ultrasonic controls.

Vac-U-Max, 69 William Street, Belleville, NJ 07109, 973-759-4600, Fax: 973-759-6449, www.vac-u-max.com.