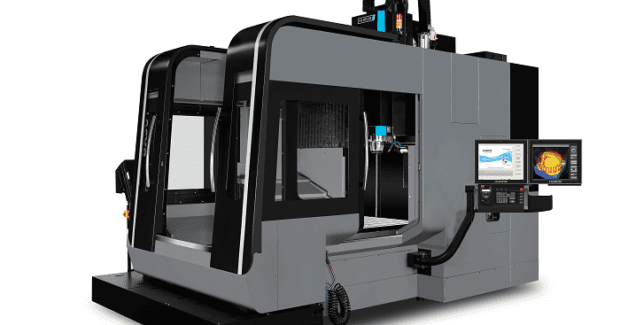

Bridge-Type Machining for Mold and Aerospace Precision

With the spindle center line being closer to the supporting structure, the dual column bridge-type BX50i from Hurco minimizes machine distortion and thermal deformation and increases rigidity with maximum support to the head casting.

Posted: July 23, 2018

In Booth S-338319, Hurco Companies, Inc. (Indianapolis, IN) adds two new models to their BXi CNC machine series as part of their 50th anniversary exhibition: the BX50i (XYZ travels 37.4 in x 53.2 in x 23.6 in) and the BX60i (XYZ travels 52.1 in x 63 in x 27.6 in). The rigidity and thermal stability of their double-column design and the overall weight of these machines provide exceptional accuracy and outstanding surface finish capabilities. Designed with the mold and aerospace industries in mind, these machines meet the needs of any high speed machining application that requires tighter tolerances. They utilize a double-column design that minimizes machine distortion and thermal deformation. The ladder design of the BX50i bridge provides maximum support to the head casting and the spindle center line is closer to the supporting structure, allowing increased rigidity. Additionally, the bridge structure is isolated from part weight and operates in a stable and predictable manner.

Specifications of the BX50i machining center include:

- Table size: 59.1 in x 37.8 in

- Table load: 5,512 lb

- XYZ travels: 37.4 in x 53.2 in x 23.6 in

- XYZ rapids: 1,535 ipm (direct drive ballscrews)

- Spindle taper: HSK 63A

- Spindle rpm: 18,000 (motorized)

- Spindle hp: 47

- Spindle torque: 88 ft-lb @ 2,800 rpm

- ATC stations: 30

- Machine weight 28,600 lb

The BX50i differs from other bridge-type CNC machines due to the integrated control that is powered by WinMax® control software and the patented UltiMotion® motion system. The control helps machinists and job shops be more productive and profitable by supporting multiple programming methods: conversational programming, NC programming, and a Hurco-specific feature called NC/Conversational Merge that optimizes efficiency even further. UltiMotion is a sophisticated motion control system that determines the optimal trajectory to run the tool, provides consistent programmed feed rates and reduces cycle time. With UltiMotion, cornering velocity is 2.5 times faster than conventional motion and machine jerk is reduced by half. UltiMotion includes up to 10,000 blocks of dynamic look-ahead and is smart enough to adapt as required by the tool path. It is different than the smoothing features offered by CAD/CAM software and improves upon CAM output by providing better handling of the machine mechanics and dynamics. All of these CNC machining centers are equipped with UltiMotion.

Hurco Companies, Inc., One Technology Way, Indianapolis, IN 46268, 317-293-5309, Fax: 317-328-2812, www.hurco.com.