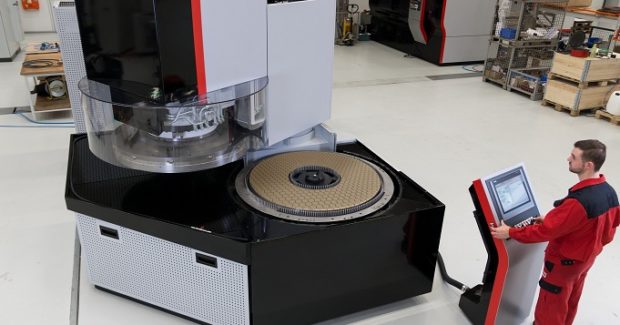

Booth N-236949: The large Spiro F12 fine-grinding machine from Supfina achieves highly precise plane parallelism (≤ 1.0 µm) for precision bearings, pump gears, valve plates, and more with a lower grinding wheel that can accommodate parts with diameters of 6 mm to 420 mm and thicknesses of 1 mm to 100 mm. It is accessed easily because the upper grinding wheel swings well out of the way, facilitating loading and unloading as well as any maintenance tasks. (first view)

Booth N-236949: The large Spiro F12 fine-grinding machine from Supfina achieves highly precise plane parallelism (≤ 1.0 µm) for precision bearings, pump gears, valve plates, and more with a lower grinding wheel that can accommodate parts with diameters of 6 mm to 420 mm and thicknesses of 1 mm to 100 mm. It is accessed easily because the upper grinding wheel swings well out of the way, facilitating loading and unloading as well as any maintenance tasks. (second view)

Booth N-236949: The small Spiro F5 fine-grinding machine from Supfina processes parts with diameters of 4 mm to 150 mm and thicknesses of 0.3 mm to 50 mm with highly precise plane parallelism (≤ 1.0 µm). Its safety shield and upper grinding wheel swing well away from the work area for loading and unloading, as well as any maintenance tasks. Parts to be finished are loosely placed in “carriers” that pins rotate in an orbiting manner. Machining takes place between two diamond or CBN grinding wheels. (first view)

Booth N-236949: The small Spiro F5 fine-grinding machine from Supfina processes parts with diameters of 4 mm to 150 mm and thicknesses of 0.3 mm to 50 mm with highly precise plane parallelism (≤ 1.0 µm). Its safety shield and upper grinding wheel swing well away from the work area for loading and unloading, as well as any maintenance tasks. Parts to be finished are loosely placed in “carriers” that pins rotate in an orbiting manner. Machining takes place between two diamond or CBN grinding wheels. (second view)

Booth N-236949: The small Spiro F5 fine-grinding machine from Supfina processes parts with diameters of 4 mm to 150 mm and thicknesses of 0.3 mm to 50 mm with highly precise plane parallelism (≤ 1.0 µm). Its safety shield and upper grinding wheel swing well away from the work area for loading and unloading, as well as any maintenance tasks. Parts to be finished are loosely placed in “carriers” that pins rotate in an orbiting manner. Machining takes place between two diamond or CBN grinding wheels. (third view)