You May Have a BIG-PLUS Spindle and Not Even Know It

Many shops are unaware that a lot of their spindles are BIG-PLUS, so they don’t realize the capabilities they possess that this system provides. If you identify these spindles on your floor and want to start taking advantage of them, there are some things you should know.

Posted: May 20, 2018

I was recently chatting with our friends at SPS Spindle Parts and Service, LLC (Goffstown, NH). They are, to my understanding, the only certified BIG-PLUS® spindle grinder in America that performs onsite regrinds. Chris Vigneault, their onsite grinding manager, explained that most of their onsite visits, BIG-PLUS or not, are the result of a crash or poor drawbar retention that allows a tool to loosen in the spindle. That isn’t usually surprising news, but Vigneault explained that their testing and examination process often does reveal something else that is very surprising for customers: “One of the things that most customers are unaware of is that a lot of their spindles are BIG-PLUS and they simply don’t know it,” he said. “Not all, but a lot of customers lately are looking for that ability and just don’t know that they already have it.”

This is common after the purchase of a used machine tool, but shops are even more surprised when they hear this news about new machines. There are a couple of reasons this happens:

- More than 150 machine tool builders are licensed to use and make BIG-PLUS on original equipment. Sometimes, to lower costs, instead of stocking two different spindles they will grind all their spindles to BIG-PLUS specifications, making it a standard option. When those machines go from manufacturing to the market or the sales team, that message may not travel with it to the sales team and, in turn, doesn’t make it to the customer. In other cases, even when builders make it clear that BIG-PLUS is an option, every machine in that series is still equipped with the system and registered in the builder’s system. Those who don’t choose the option simply don’t receive some of the supporting documents about care, usage and tool selection.

- Another way BIG-PLUS spindles make it to the floor without shops knowing is that the in-house installation supervisor may be told by the OEM’s application engineer, but that information doesn’t necessarily flow much further than that.

All of which begs the question, how do you find out if you have a BIG-PLUS spindle?

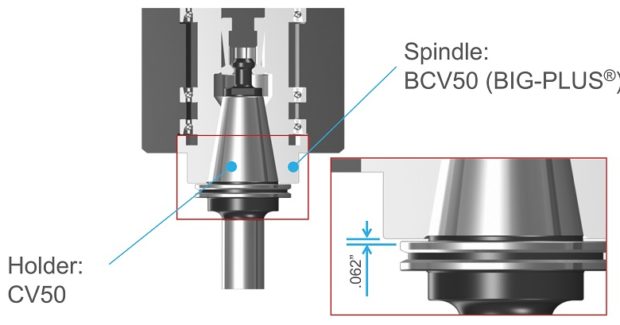

We have learned over the years which builders are making their spindles to BIG-PLUS as a standard or as an option, and on which models. So when I visit a customer or talk to them over the phone, I ask what brands of machines they use and compare this with the master list of authorized machine tool builders for BIG-PLUS. However, the easiest way to figure it out is to place a standard tool into the spindle and see how much of a gap there is between the tool holder flange face and spindle face. Without BIG-PLUS, the standard gap should be visible, or about .12 in. If it is BIG-PLUS, the gap is half of this amount, or only .06 in. These values change depending on 30 taper, 40 taper or 50 taper sizes, but the gap is visibly less than usual.

If you identify BIG-PLUS spindles on your floor and you want to start taking advantage, there are some things you should know. First, if you’ve been using standard V-flange tools in that spindle, you likely won’t be able to realize the full benefits of the system. Over time, standard tooling will wear the spindle in ways that change its geometries. “We were just at a shop in Connecticut checking out a BIG-PLUS spindle,” recalled Vigneault. “Because of the way it wears when you don’t use BIG-PLUS tooling – which is exactly the way this customer was using the machine – the face was very heavy, or oversized. If we were grinding it back into spec, it would probably take quite a bit of work. We would have to take a lot of material off the face to get there.”

Because both taper and face contact are what make the system shine, the geometry is critical. If someone trying to transition to BIG-PLUS tooling after learning they have the spindle doesn’t understand that, they won’t experience the performance they expect. There’s also the factor of maintenance. If a shop didn’t know it had BIG-PLUS machines, it’s a safe bet they didn’t take the preventive steps to help preserve the crucial geometry. These include keeping the spindle, tools and carts clean; misaligned automatic tool changer arms can also harm a BIG-PLUS spindle. These very reasons are why we offer spindle and tool taper cleaners, as well as arm alignment tools. Also, resist the temptation to use less expensive, unlicensed dual-contact tools if you want to give the system a shot. These tool makers do not have the master gauges necessary to create the correct geometry . . . for reference, read my January 2016 Depth of Cut column titled “Is BIG-PLUS an International Standard?” It shares comparative test results and details the risks.

There’s really one proven way to restore a BIG-PLUS spindle to proper specifications: with a certified regrind. Just as tool makers need the right gauges and measuring devices, so do spindle grinders. If you discover you have BIG-PLUS spindles and want to take advantage, keep these factors in mind to see what the system can do.