Vacuum Furnaces for Aerospace Brazing and More

Customized MetalMaster and TITAN vacuum furnaces from Ipsen provide precision gas quenching for aerospace brazing and other high vacuum applications, particularly with thin section parts and lighter pieces.

Posted: May 28, 2018

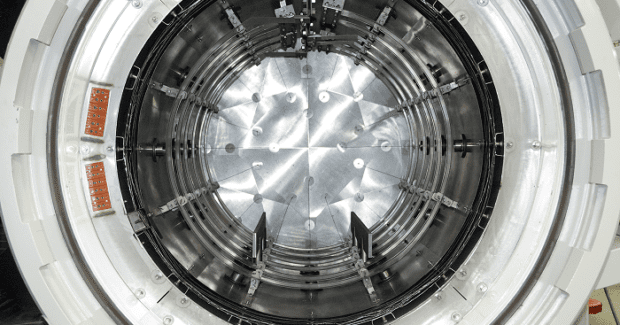

Ipsen USA (Cherry Valley, IL) built a horizontal-loading MetalMaster® vacuum furnace with two-bar gas quenching for a commercial heat treating company in South Carolina. Ideal for aerospace brazing and other high vacuum applications, this vacuum furnace line performs distinctively well with thin section parts and lighter pieces. The customized furnace features a 36 in x 30 in x 48 in (914 mm x 762 mm x 1,219 mm) graphite work zone with a carbon steel gas distribution plenum and molybdenum heating elements, as well as a 2,000 lb (907 kg) load capacity. It operates at temperatures of 1,000 deg F to 2,400 deg F (538 deg C to 1,316 deg C) with ±10 deg F (±6 deg C) temperature uniformity. The furnace is also equipped with a 20 in diffusion pump and CompuVac® controls system. This MetalMaster furnace can also meet applicable AMS 2750E requirements and provide tight temperature tolerances with DigiTrim® controls settings. It also offers a specially engineered heat exchanger and turbine blower that is designed to optimize gas flow for more efficient cooling.

Another commercial heat treater, Midwest Thermal-Vac Inc. (MTV; Kenosha, WI), purchased a TITAN® vacuum furnace with 12-bar gas quenching that features a diffusion pump for high-vacuum levels and an all-metal hot zone measuring 18 in x 24 in x 18 in (455 mm x 610 mm x 455 mm) to ensure part cleanliness – an important feature for processing aerospace parts that need to comply with NADCAP and others that meet medical industry requirements, such as MedAccred. It has a 1,000 lb (450 kg) load capacity and is capable of operating at temperatures ranging from 900 deg F to 2,400 deg F (482 deg C to 1,316 deg C) with ±10 deg F (±6 deg C) temperature uniformity. This unit includes a PdMetrics® software platform for predictive maintenance and Ipsen startup service performed by local field service engineers.

Commercial heat treater Rockford Heat Treaters Inc. (RHT; Rockford, IL) recently purchased a TITAN H6 to expand their production capacity and cater to increased demand. It has a 36 in W x 36 in H x 48 in D (915 mm x 915 mm x 1,220 mm) all-graphite hot zone with a 3,000 lb (1,361 kg) load capacity and is equipped with a diffusion pump that allows them to meet aerospace requirements and process sensitive materials that require deep vacuum levels.

Ipsen USA, 984 Ipsen Road, Cherry Valley, IL 61016, 815-332-4941, Fax: 815-332-4549, www.ipsenusa.com.