The Heat is On

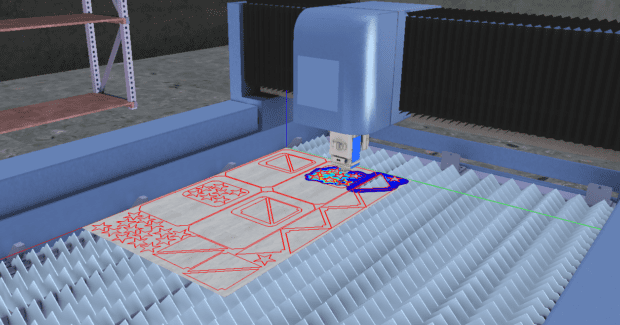

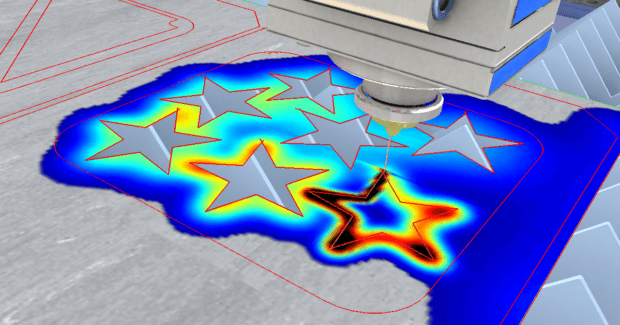

To select the best sheet metal strategy and cutting order, users of this 3D simulation software can calculate graphically and interactively how heat sources affect sheet metal during the laser or plasma cutting process.

Posted: May 28, 2018

To develop 3D simulation that allows the user to calculate graphically and interactively how heat sources affect sheet metal during the laser or plasma cutting process, Lantek Systems, Inc. (Mason, OH) has collaborated with Vicomtech (Visual Interaction and Communications Technologies Center Foundation; San Sebastián, Spain) to launch BeroSim simulation software. The simulation of the impact of heat on the sheet metal cutting processes enables the selection of the best sheet metal strategy and cutting order, substantially improving performance since it possible to anticipate and detect possible unforeseen anomalies during the layout phase.

By simulating the process using BeroSim, the effects of cutting do not need to be tested on the actual machine. This results in savings in machine time, materials and energy, while at the same time lessening the risk of possible breakdowns or workplace accidents. Now the user will be able to see, through a simulation, how heat propagates and is distributed in the sheet metal as it is cut and how this affects the material. Plasma and laser technologies locally increase the overall temperature of the sheet metal which modifies the properties of the material and can alter its characteristics (thickness, etc.).

Engineers can use the simulation to define the sheet metal cutting strategy and the cutting and machining order, preventing possible material deformation during cutting to obtain optimum quality products. Likewise, the user can correct the cutting path and trajectory of the machine to maintain the quality of the sheet metal products.

“Digital transformation has become highly important in the industrial sector, which needs advanced technological systems that provide added value, something that is only possible with research and innovation,” explains Dr. Iñigo Barandiaran, the head of Vicomtech’s Department of Industry and Advanced Manufacturing. “This sector must continue to be an economic engine and guarantor of stable employment, and this will be achieved with the help of technology.”

“With this software, we contribute to this process of change and to the modernization of the sheet metal machining, simulation and verification sector, providing a set of functionalities and innovative capabilities that provide greater efficiency to production processes,” notes Susana García, the head of CAD/CAM systems development at Lantek. “This enables the optimization of material, human and economic resources. This collaboration helps us to promote the implementation of productive models and methodologies that will allow users of our systems to achieve greater competitiveness and efficiency.”

This project represents a scientific breakthrough regarding the state-of-the-art in sheet metal technology. “Understanding how heat sources affect sheet metal cutting processes is essential in the design of efficient simulation tools. The success of this software is a consequence of the fluid relationship between our two companies,” added Dr. Aitor Moreno, a Vicomtech researcher and expert in industrial process simulation techniques.

Lantek Systems, Inc., 5412 Courseview Drive, Suite 205, Mason, OH 45040, 877-805-1028, Fax: 513-322-4567, [email protected], www.lanteksms.com.