Robotic Guidelines for the Production of Safety Critical Welds

Security features, tracking, arc monitoring and traceability make it nearly impossible to stray from established protocols and parameters that maintain weld integrity during the robotic welding of safety critical welds. It may take a considerable amount of upfront work to get to full data harmonization, but the results are confident customers and improved product quality that can help secure future operations.

Posted: May 20, 2018

Precisely welding joints is crucial for manufacturers, particularly for OEMs and suppliers to the transportation industry. End users expect weld quality to meet the high level of performance required, especially where poor weld integrity could be detrimental to life or property. Automotive seats, for example, are in direct contact with passengers, so seat welds are considered “safety critical” to an assembly. This classification dictates a particular protocol prior to production. Although OEM requirements vary, they tend to be consistent with industry practice and are implemented with minor differences depending on the part, plant and industrial equipment being used. Either way, to maintain weld integrity during the robotic welding of safety critical welds, basic guidelines must be followed.

PRE-PRODUCTION PROTOCOL

Before production, establishing weld parameters and verifying their acceptability is key. This can be done by cutting and etching weld sections to confirm the accuracy of weld penetration (15 percent to 20 percent). Once the penetration of the weld has been verified, this normally results in approval of the welding procedure. Destructive testing of the weld may also be required. The manufacturer has a process to release the cell for production once the weld tests are approved. If the part being produced should require a change to an essential variable beyond certain limits, a revalidation through cut and etch testing is advised. Automotive OEMs will often specify a frequency of destructive testing as a means to verify that quality is being maintained.

PRODUCTION PROTOCOL

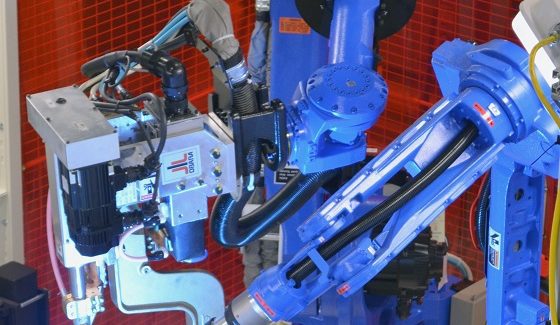

Robotic welding improves part quality by having the ability to always place welds in the exact same location via programmed parameters, and the adherence to certain procedures contributes to high quality welded products. Automotive manufacturers that produce safety critical welds have been focusing on some key production elements – security, tracking, arc monitoring and traceability. Following proper production protocols for these aspects during the robotic welding of parts enables manufacturers to reliably create products that meet demanding customer needs:

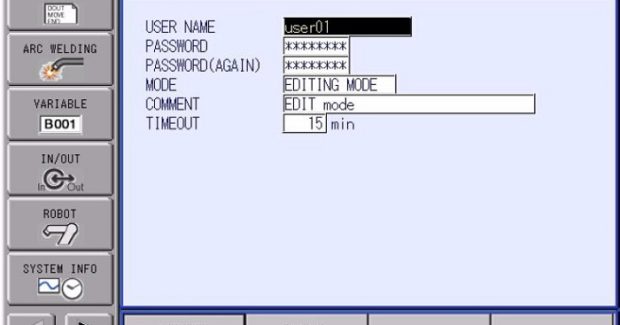

- Security. It is of the utmost importance to verify only qualified personnel are supporting production equipment. Moreover, the changes made with certain equipment, such as a robot in a robotic weld cell, should be monitored carefully to maintain the integrity of the production process and the quality of the manufactured components. A security system with a global password is convenient for multiple technicians to maintain numerous robot cells within a plant. However, global passwords risk being shared among plant personnel, with no control of what is being changed and by whom. Robot controllers combat this issue with a password function that allows the creation of a database of users with unique passwords and security level clearances. What these levels permit users to do and access is defined by the system, and the level to which management controls access will vary by plant location. In some cases, software allows remote password control by PLC, giving controls engineers the ability to implement logic to use plant/cell-based controls to remotely administer users and logins.

- Tracking. Security levels can help ensure that only qualified personnel are accessing the equipment, but what are they doing? Robot controllers can log changes to the program with a date, time and User ID if a password function is used. If a non-conforming part is detected in the robot cell, this change log can help manufacturers pinpoint if the issue is due to a change in the program. A time range should also be identified for the parts that require further inspection. This can be invaluable for automotive plants who often run three shifts a day, frequently changing operators and maintenance staff.

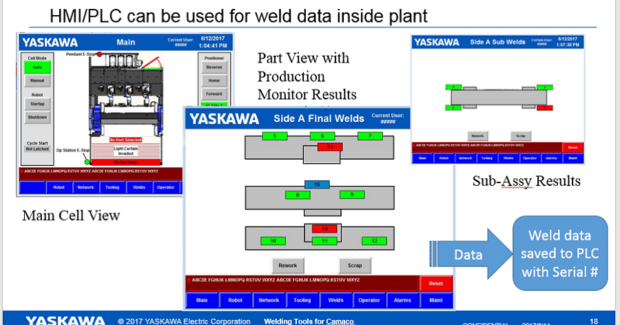

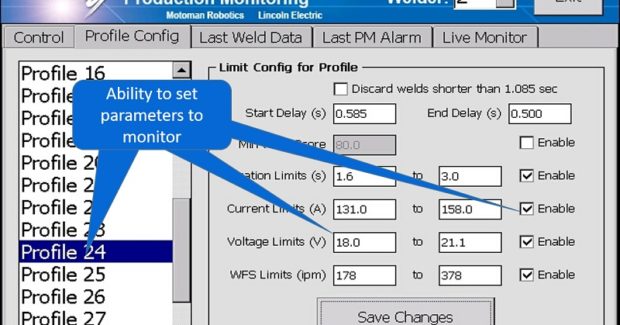

- Arc Monitoring. Savvy robot suppliers are now designing welding interfaces to support arc monitoring capability that power source manufacturers may have integrated. These integrated features are accessible from the robot teach pendant and, in some cases, have documentation and data analysis systems that can connect multiple power sources, enabling the precise evaluation of numerous welding parameters. The challenge to meet safety critical mandates also entails clearly presenting weld results from power source arc monitoring into a useful format. The best format is to highlight monitor results on a part diagram on a robot cell HMI. This allows weld station operators to easily spot weld locations that have failed their limits and quickly react to inspect whether the welds are conforming or non-conforming.

- Traceability. Automotive OEMs are not just asking their suppliers to make good parts, they are specifying quality systems to provide “traceability” that will associate a part’s weld results with its serial number, enabling the ability to trace back to a point in production when parts were known to be conforming if a non-conforming part is detected. To help manufacturers meet traceability, the arc monitoring data from the welding power source and robot controller must be captured and associated with the part serial number. The cell PLC is logging weld data plus any part-specific data that needs to be saved and accessed remotely.

IMPLEMENTATION

When handling weld monitoring data, production control considerations must be made along with historical logging and traceability requirements. While the use of the information should make it simple for operators on the floor to focus on part quality, historical data can be used by supervisory personnel to administer quality plans and troubleshoot difficulties. Automotive manufacturers have been applying enhanced production standards for safety critical welds for years. Security features make it nearly impossible to stray from established protocols and parameters, and arc monitoring delivers real-time, graphic indications of welds that need further inspection. Although it may take a considerable amount of upfront work to get to full data harmonization, the results are confident customers and improved product quality that can help secure future operations.