Linear Friction Welding: Not Just for Aerospace Parts Production

High cost and large size have always been the main reasons why linear friction welders have seen limited use outside of aerospace applications. But that is changing with a new line of affordable LFW systems that have a much smaller footprint and utilize a patented electro/mechanical oscillation device that is new to the world of linear friction welding.

Posted: May 21, 2018

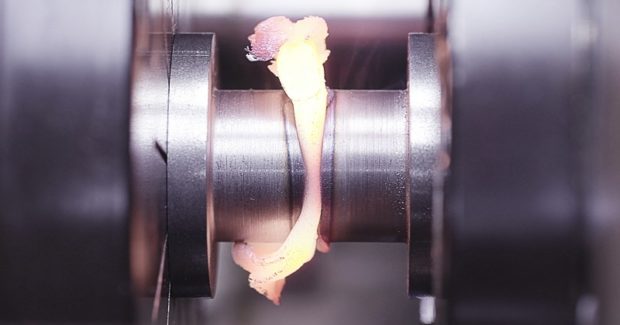

Linear friction welding (LFW) is a very consistent and fast solid-state joining process that is used in several aerospace applications. Two parts are pushed together, one oscillating at a high frequency, to create friction that heats the metals to a temperature at which they are able to join together. When the oscillation stops, the parts cool to form a forged-quality weld. The process takes as little as a single second to create a weld. Very little surface preparation is required for joining because any imperfections and impurities are removed along with a layer of surface metal as flash. No consumables are required, no harmful fumes are produced that require exhausting, and any potential issues associated with solidification (such as segregation or porosity) are bypassed.

Taylor-Winfield Technologies, Inc. (Youngstown, OH), a custom machine builder specializing in material joining, induction heating and automated assembly systems, has developed a line of advanced LFW machines. In collaboration with APCI, LLC (South Bend, IN), Taylor-Winfield is utilizing their patented electro/mechanical oscillation technology to offer a more cost effective machine platform for solid-state bonding. This innovative machine line changes the whole landscape of linear friction welding and solid-state bonding. Linear friction welding has been proven to increase performance and accuracy over traditional material joining processes. The patented IP provides superior positional accuracy, flexibility and control for joining various shapes and dissimilar metals. The applications for this technology are endless, but this new line of advanced machines will concentrate on aerospace applications and beyond, including transportation, automotive and energy sectors.

“Linear friction welding has seen limited use outside of the aero-engine world,” explains Frank Deley, the product manager of the LFW line at Taylor-Winfield. “It is an established technology for fabricating bladed disks or blisks used in jet engines, and it is also used to build aircraft structural components. The high cost and large size of these welders have been the main reasons why this proven process has seen limited use outside of the aerospace market. But we are now changing this dynamic by introducing a line of LFW systems that are affordable and have a much smaller footprint. We are utilizing a patented electro/mechanical oscillation device that is new to the world of linear friction welding. Our goal is to service the aerospace arena, but also bring this solid-state bonding process to mainstream parts production and other material joining manufacturing needs throughout the world.”

The company has equipped their own research and development laboratory with LFW machines that are used for parts process testing and proof-of-concept verification. “We are able to demonstrate how this joining process can improve parts production processes and help reduce our customer’s manufacturing costs and improve quality,” added Deley. Linear friction welding was first introduced in 1969, but early machine process constraints, extremely high capital investment and maintenance costs limited the technology to a small number of manufacturers who could afford the space and capital investment. Taylor-Winfield addressed those design concerns and market limitations with new features and techniques that have not only drastically reduced maintenance and machine costs, but have also taken an older, conventional technology and successfully ushered it into the 21st century.

Taylor-Winfield Technologies, Inc., 3200 Innovation Place, Youngstown, OH 44509, 330-259-8500, Fax: 330-259-8538, taylor-winfield.com.