It IS Rocket Science: A Workcell for Forming Aircraft Components

This press manufacturer was challenged to build a sophisticated system that could form aircraft parts with complex geometries in a low volume, high mix production environment, using a fully automated die handling system and the largest staging table of its kind in the world for continuous production. The result? Die change time reduced from two hours to ten minutes.

Posted: May 21, 2018

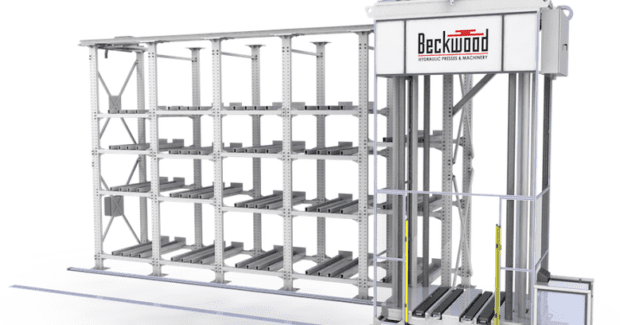

Beckwood Corporation (Fenton, MO), a manufacturer of custom hydraulic presses, automation systems and the Triform line of precision forming equipment, excels at developing sophisticated, robust aerospace forming technologies that are engineered for accuracy and repeatability. Recently, a fabricator that produces various components for commercial and military aircraft came to them for a turnkey package consisting of two 1,400 ton hydraulic presses and two automated stamping die handling systems to load and unload the presses more efficiently than the conventional forklift and manual labor that was being used. The presses and quick die change (QDC) workcells would form a variety of parts in relatively low volumes, so the system needed automated die handling and a 42 in diameter deep draw sheet hydroforming press with a staging table – the largest of its kind in the world.

A critical part of this project involved the need for a QDC system with 15,000 lb capacity to feed each hydraulic press. “We conducted a thorough review with all of our local die cart suppliers and they all passed on the bid, citing too many obstacles on that large a load,” explained John Harte, the lead electrical engineer at Beckwood. “So we decided to design, engineer and build the system ourselves.” Each press has a footprint approximately 30 ft square, and the QDC would need to service the presses with T-table staging devices that allow the next die to be prepped and ready to insert upon completion of the previous run cycle. With the degree of automation involved, Beckwood worked with the fabricator’s engineering staff to devise a workcell concept comprised of two four-post presses, each with a QDC system including a cart, rack and T-table with 15,000 lb load capacity. Each press would be over 33 ft in tall and positioned in a 10 ft deep pit.

Motion control and HMI from Siemens Digital Factory (Norcross, GA) was specified by the fabricator for this project, so Harte connected with Derek Eastep, an account manager for Siemens, and the equipment list for the project began to take shape with various drives, PLCs, displays and motion controllers. Motion control was a critical component required to operate all press movements, as well as the motor starters, QDC integration, light curtains that protect the workcell and operators, plus area scanners that maintain the integrated safety condition monitoring on the entire cell. The system logic and data logging setup was done by the fabricator, who already had experience with Siemens controls, with the Beckwood team integrating the QDC and overall cell management.

The QDC operates in tandem with the two presses, using four 15 hp motors to drive the lead screws on this massive die handling system. They are electrically geared through an onboard S7-1515 PLC to move the ram and shuttle. Additional motors and drives on the feed tables allow the next die to be positioned during press operation. When a press cycle is completed, the air bags on the feed tables lift the next die for positioning onto the QDC, then a shuttle inserts the die inside the press, with all motion controlled by the PLC. These T-tables and the QDC were designed, engineered, built and tested in the Beckwood factory prior to shipment and installation at the fabricator’s facility, where personnel from both Beckwood and Siemens were active in the commissioning of the entire system.

The S7-1515 PLC is a robust controller that integrates function control, safety and condition display in a single module with Profinet protocol for bus communication. Through the TIA Portal and Step 7 software, the end user can customize the operation of the devices remotely, integrating multiple part files and related safety commands in one controller. This “library” feature allows the end user, as they run a variety of parts during a shift, for example, to use one software package to program quickly and more efficiently. Likewise, the safety switches on the entire system are programmed through this secure and redundant safety back-up software through the TIA Portal. All motor movements on the twin four-post presses are controlled with Siemens drive technology. In operation, the presses with the QDC systems should reduce die setup and changeover from approximately two hours to ten minutes.

“All parties had good familiarity with our protocols,” noted Eastep. The two presses in the workcells are robust four-post frame styles with replaceable, graphite-impregnated bronze bushings and solid chrome-plated posts to ensure precision ram guidance. The Triform deep draw sheet hydroforming press is designed to form parts with challenging geometries in low volume, high mix production environments. “We used the Selector, Sizer and Starter engineering tools from Siemens to spec and then commission the drives, which saved us a substantial amount of time,” added Harte. “It made our lives a lot easier.”

Beckwood Corporation, 889 Horan Drive, Fenton, MO 63026-2405, 636-343-4100, www.beckwoodpress.com.

Siemens Digital Factory, 5300 Triangle Parkway, Norcross, GA 30092, 678-427-8319, www.siemens.com/businesses/us/en/digital-factory.htm.