Fast, Cost Efficient Production of Near-Net-Shape Metal Aerospace Parts

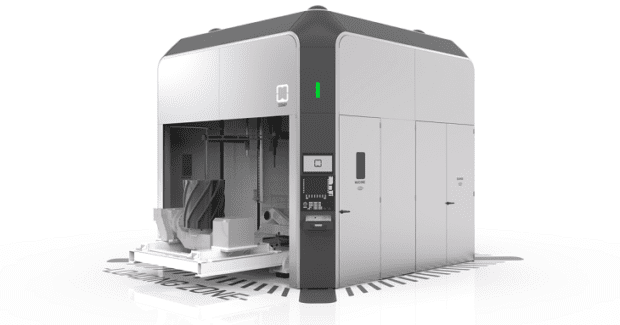

Modular 3-axis and 5-axis GTarc machines from GEFERTEC use 3DMP additive manufacturing technology to build each part welding layer-by-welding layer for maximum material utilization that leads to substantial cost savings of up to 60 percent on expensive materials like titanium.

Posted: May 25, 2018

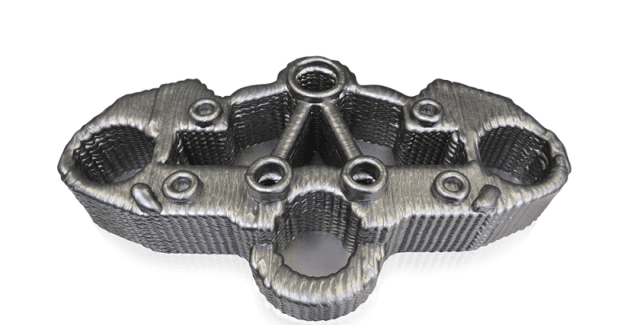

GEFERTEC GmbH (Berlin, Germany) offers their revolutionary 3DMP® additive manufacturing technology for cost efficient and fast production of near-net-shape metal parts with quality that is comparable to standard manufacturing methods. This AM technology is based on well-proven electric arc welding and uses wire as the original material so that the final part is formed welding layer-by-welding layer. This method offers a range of advantages compared to other additive manufacturing technologies that use powder as the original material. For example, there is no elaborate powder handling and most standard materials are available as wire at significantly lower prices. The main benefit is the high production speed, which can be up to 600 cm3 per hour, depending on the material. 3DMP is ready to use in the new 3-axis GTarc machine for parts up to 3 m3, and in the 5-axis GTarc machine for parts up to 0.8 m³. These characteristics show how this machining center is ideally suited for the production of complex and larger parts made of steel, nickel, titanium, or aluminum.

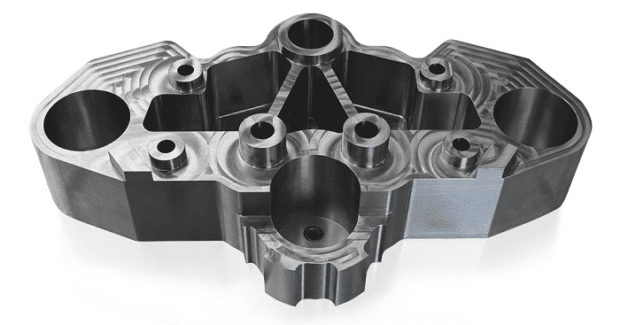

Special 3DMP CAM software calculates the data out of the CAD-modeled part, which enables the CNC-control unit to position the welding head with high precision. The machine produces the near-net-shape part automatically. The finishing of the part is done externally with a standard CNC milling machine. Compared to other manufacturing methods, 3DMP has maximum material utilization that leads to substantial cost savings, especially when expensive materials like titanium are used, making it ideal for aerospace applications and other industries. Depending on the application, manufacturing costs decrease up to 60 percent. For example, consider a bearing holder of nickel-chromium steel 1.4305. In conventional manufacturing, a 452 mm x 245 mm x 100 mm block weighing 85 kg must be milled on a CNC machine. The final part weighs only 18 kg, meaning more than 80 percent of the material is converted into chips. The total cost amounts to $5,297, including $1,177 in material costs and $4,120 in milling costs.

In contrast, when using 3DMP on a GTarc machine the near-net-shaped part weighs only 25 kg and can be produced for only $883. Subsequent milling amounts to $1,472 and produces only 28 percent chips. In total, the total cost of $2,355 saves more than 50 percent compared to conventional manufacturing. Though this comparison is based on estimated costs that could vary depending on the company, it proves the enormous potential of additive 3DMP technology. And GTarc machines are modular, so that making future upgrades is very easy: a shop can integrate a pan-tilt-table into a 3-axis machine to upgrade into a 5-axis system. Prices of GTarc machining centers are in the range of a smaller CNC milling machine and are considerably lower than comparable machines for 3D printing.

GEFERTEC GmbH, Schwarze Pumpe Weg 16, Berlin, Germany 12681, +49-30-912074-360, [email protected], www.gefertec.de.