Why are Three-Flute Drills Better?

The idea of adding a third cutting edge to drills for higher feed rates is nothing new, but the challenging chip evacuation made them suitable for only a few applications, such as machining cast iron. So how has this supposed slow seller made it into the top league of high performance tools for steel machining? A new design has harnessed the advantages of the three-flute drill for long-chipping steels and stainless steel materials.

Posted: April 24, 2018

Three-flute solid carbide drills have already been around for some time. The first tools of this kind came onto the market around 50 years ago. They are now used as part of a reliable process in the machining of cast iron. The advantage is that they have a higher feed rate due to the third cutting edge. However, up to now three-flute drills have been ill-suited for long-chipping materials because they could not evacuate the metal removal rate increased by the third cutting edge due to the design with smaller flutes. Because of the inadequate flow of chips, the risk of a chip jam is increased and there is a risk of tool breakage. As a result, three-flute drills have not been widely used until now and, over the decades, the idea has been put to bed, so to speak.

CLEAN WORKING ZONE

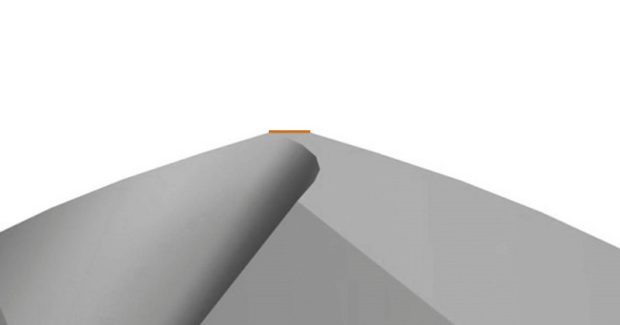

Last year, the new three-flute Garant MasterSteel Feed solid carbide drill was introduced for the first time. This drill produces a 50 percent higher feed rate per revolution, even in long-chipping steels and stainless steel materials, and it also offers extraordinary durability. To achieve this, the shape of the point geometry, the capacity for precise chip breakage and chip evacuation have been optimized in particular. The design of the point geometry is crucial when it comes to evacuating the chips away from the working zone quickly and reliably. This goal was achieved with a new, patent-pending point geometry. As a result, the chips are sufficiently compressed in the area of the point geometry and are even broken when processing ductile materials.

WORLD’S LARGEST L/D RATIO

In order to evacuate the chips discharged by the three cutting edges as part of a reliable process, particularly large chip flutes are required. For this reason, the Garant MasterSteel Feed drill has undergone core tapering that enables larger chip flutes towards the end of the twist section, combined with sufficient stability of the core. The importance of the twist section design was also demonstrated by the structure of the longer 8xD and 12xD drills. The development of these tools took a particularly long time. As part of this design, the spiral angle had to be optimized multiple times and was modified until the necessary process reliability was achieved. New three-flute drills with the world’s largest L/D ratio came onto the market a year after the market launch of the first Garant MasterSteel Feed solid carbide drill. The chip evacuation is now so efficient that it functions as part of a reliable process in various materials. It was possible to demonstrate this in internal tests with materials such as St37, C45, 42CrMo4, X155CrVMo12.1, X5CrNi18-10.

LONGER TOOL LIFE WITH A CONVEX CUTTING EDGE

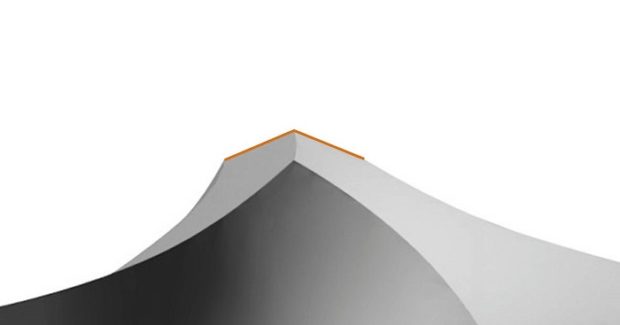

To increase tool life, the cutting edge design from the classic two-flute drills (known as the “S-cutting edge”) has been transferred to a three-flute tool for the first time. With a convex cutting edge, the cutting force acts towards the tool in the area of the cutting edge corner – this stabilizes the cutting edge corners. With a concave cutting edge design the opposite is the case, meaning the cutting edge corners are more susceptible to breakage. This was demonstrated by practical tests using the new Garant MasterSteel Feed solid carbide drill and conventional three-flute drills, including tests with alloyed heat treatable steel 42CrMo4.

In the test, drills with a diameter of 8.50 mm and an overall length 6xD competed against each other. They were clamped in hydraulic chucks and drilled at a feed rate of 0.44 mm/rev and a cutting speed of 140 m/min. The result: Tool breakage during spot drilling and tool life travels that were too short for the conventional three-flute drills; longer tool life travels for the drills with an adapted point geometry and concave cutting edge shape; 2,702 holes and a tool life travel of 102 m with the new drill concept. The new drill was the clear winner in this test.

UP TO 50 PERCENT HIGHER FEED RATE

As well as reliable chip evacuation, the force and torque characteristics of three-flute drills must also be taken into account because there are higher feed forces due to the design. The test series have shown that with the same cutting data, different feed forces occur depending on whether it is a two or three-flute drill design. Depending on the tool, the difference was between 46 percent and 59 percent. This was mainly due to three cutting edges being engaged in the material at the same time rather than two. The action of a third cutting edge enables up to 50 percent higher feed rates per revolution. However, it is commonly known that an even higher feed force is produced as a result. Tests have confirmed this relationship:

- For the material 42CrMo4, the 57 percent higher feed rate (from 0.28 mm/rev to 0.44 mm/rev) produced a 40 percent greater feed force.

- For X155CrVMo12 material, the approximately 50 percent higher feed rate produced a 41 percent greater feed force.

- In the material 16MnCr5, the higher feed rate of 64 percent increased the feed force by 35 percent.

If the two effects described above are now added to the feed force, the following conclusions can be drawn with regard to the field of application for three-flute drills:

- The workpieces and clamping should be stable.

- For tools with a diameter larger than 12 mm, the machine spindles should be able to provide high torques at low and medium speeds.

PRECISE SPOT DRILLING AND ACCURATE DRILLED HOLES

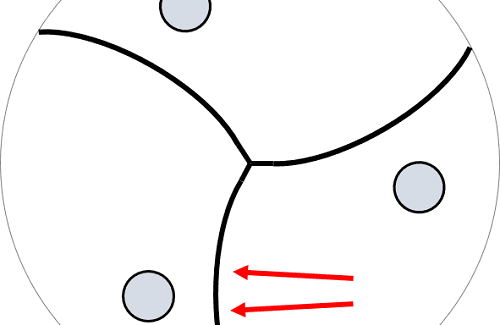

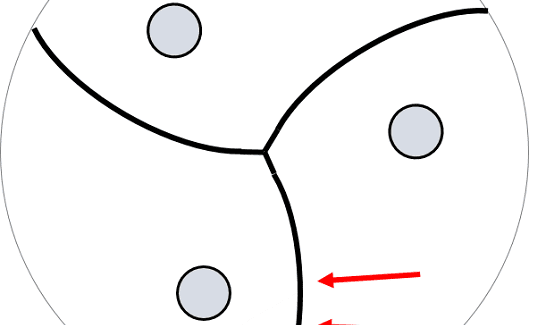

Due to the third main cutting edge, three-flute drills also offer significant advantages when spot drilling. The three main cutting edges run in curves to the center of the tool and form a tetrahedrally-shaped chisel point where they meet. However, in the case of the two-flute drill, the main cutting edges end in a chisel point that connects both the main cutting edges in a line. The difference can be seen in the spot drilling behavior. In the case of the classic two-flute drill, the chisel point meets the material at several contact points at the same time; there is no clear fixed point. As a result, the tool may start to wobble. This happens in particular when spot drilling uneven surfaces. The three-flute drill, however, has a punctiform chisel point. This means the first contact between the material and the tool takes place at a precisely defined position. Once the tool has penetrated the material, the process forces act on the “edges” of the chisel point and also promote the self-centering capacity of the drill. It is therefore possible to prevent the tool from drifting, even on uneven surfaces.

These features make the three-flute concept perfectly suited for the design of NC spotting drills. It is advisable to prepare the drilling position precisely for the following tool by spot drilling, particularly if deep holes need to be drilled with tools measuring 8xD or even 12xD. This means the world’s first three-flute NC spotting drill has been developed and, with a calculated point angle of 155 deg, it has been optimally matched to the Garant MasterSteel Feed drill.

CONCLUSION

Constructive improvements have made it possible to harness the high feed potential of the three-flute drill for use on more materials and even for long-chipping materials such as X5CrNi18-10, and for general structural steels such as St37. Changes in the area of the point geometry and the spiral angle, convex cutting edge shapes and a tetrahedrally-shaped chisel point were the factors for success.