Turn Every Design into a Successful 3D Print

Sunata software from Atlas 3D works seamlessly with direct metal laser sintering printers, eliminating the expensive and time-consuming simulation process that plagues 3D design engineers.

Posted: April 16, 2018

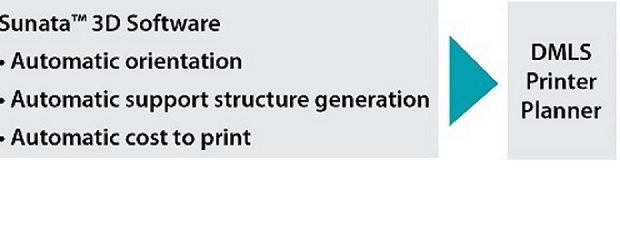

Sunata™ software from Atlas 3D Inc. (Plymouth, IN) ends the trial-and-error guesswork of metal additive manufacturing. Designed to work seamlessly with direct metal laser sintering (DMLS) printers, it automatically chooses the best orientation for a part and generates the necessary support structures for a successful build, eliminating the expensive and time-consuming simulation process that plagues 3D design engineers. Users download their designs directly into a cloud-based program and automatically receive the optimal orientation and associated support structures. There are no servers to install and configure, no IT support is needed. Users simply import the .STL CAD file and the software does the rest. The accuracy and speed of the software comes from its patent-pending Thermal Circuit Network (TCN) that scientifically parses the print design into thermally similar layers, which are then divided into thermally similar segments. The TCN applies its thermal modeling algorithm to arrive at the optimal orientation and support structure for that design after running it through 100 different orientations.

Other simulation and orientation programs force users to “guess” at the optimal orientation and support structures and then simulate the print process for a proposed solution. In contrast, the TCN scientifically determines the optimal orientation and support structure to yield a successful 3D build the first time and every time. The technology group at ITAMCO (Indiana Technology and Manufacturing Company; Plymouth, IN) worked with the developers at Atlas 3D to create Sunata. The team appreciated the need to balance minimal distortion with reduced print times. They wanted to profitably print viable components with additive manufacturing, not just print prototypes. This software gives users the ability to scale their requirements from next-to-zero distortion with longer print times, to more tolerable distortion with shorter print times.

Since Sunata optimally orients and supports the part for printing, it can accurately provide the total print time and amount of sintered material the design requires, thereby providing accurate cost-to-print data. Knowing this information, in combination with eliminating waste and rework, enables users to profitably print their designs. The software works with many metal feedstocks and is the first additive manufacturing software platform to test the new Ferrium® C64® (AMS 6509) metal powder from QuesTek Innovations LLC (Evanston, IL). Ferrium C64 is a high strength, high-surface hardness, and highly fracture-resistant carburizable steel that also has high temperature resistance and hardenability. C64 steel is a performance upgrade from 9310, X53 (AMS 6308), EN36A, EN36B, EN36C and 8620 that can achieve a surface hardness of 62-64 Rockwell C (HRC) via vacuum carburization.

ITAMCO is already manufacturing components using Sunata with an M 290 3D printer from EOS North America (Troy, MI), and they are especially interested in the QuesTek metal power. One leading application for Ferrium C64 steel is for demanding Bell Helicopter and Sikorsky transmission gearboxes. Under an Army-funded Future Advanced Rotorcraft Drive System (FARDS) program, Bell and Sikorsky are evaluating and qualifying Ferrium C64 steel to displace Alloy X53 (AMS 6308). Benefits would include lighter-weight gear components, increased power density of the helicopter transmission, greater temperature resistance, and better pitting and corrosion resistance. In addition, QuesTek is evaluating and demonstrating Ferrium C64 for the Additive Manufacturing of aerospace gears and fatigue-driven applications under an Army-funded SBIR Phase I program.

Other possible applications for the metal powder include racing transmission gears, gears with integral bearing races, and integrally geared drive shafts where durability, compactness, weight savings, high resistance and high-surface fatigue resistance are valued. Ferrium C64 steel can also offer increased performance and reliability of wind turbine transmission gearboxes, thus reducing maintenance costs and downtime and increasing reliability. Given that ITAMCO provides open gearing and precision machining services to many heavy duty industries, including aviation, energy, mining, off-highway vehicles and marine, Sunata and Ferrium C64 could lead to continued advancement in their additive manufacturing program.

“As metal additive printing continues to grow, so too does the need to add new printable powders,” said Chad Barden, the chief executive officer of Atlas 3D. “The thermal characteristics of these new powders, however, present their own unique set of challenges. ITAMCO is one of our many customers to benefit from our forward-looking move to add this exciting new material to our list of available metals in Sunata. As with all of the other materials, users can successfully print their designs with the touch of a button, every time. Without question, that software brings certainty to the arduous, trial-and-error process associated with the introduction of a new powder.”

“ITAMCO is a long-time manufacturer of high quality gears and an early adopter of Ferrium C64 steel powder for additive manufacturing applications,” added Jeff Grabowski, the manager of business development at QuesTek. “The incorporation of Ferrium C64 steel into the Sunata system will enable others interested in C64 to more efficiently begin building components with this high performance steel.”

Atlas 3D Inc., 6100 Michigan Road, Plymouth, IN 46563, 574-914-4447, www.atlas3d.xyz.

ITAMCO, 6100 Michigan Road, Plymouth, IN 46563, 574-936-2112, www.itamco.com.

QuesTek Innovations LLC, 1820 Ridge Avenue, Evanston, IL 60201, 847-328-5800, www.questek.com.