Software Tools Provide Competitive Advantages in Appliance Manufacturing

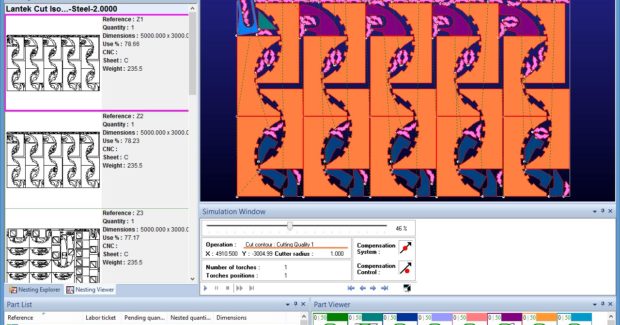

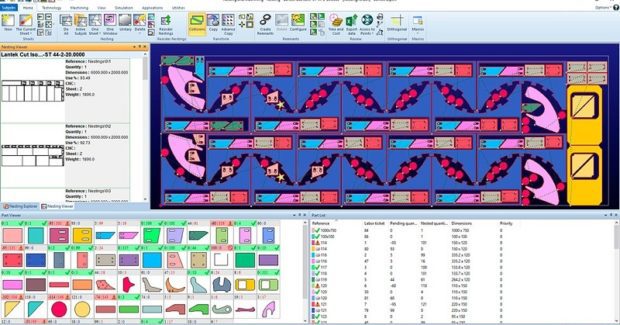

Software tools from Lantek Systems can maximize the profitability of design, nesting and sheet metal fabrication processes used in building stoves, washers, dishwashers, ovens or other home appliances.

Posted: April 14, 2018

Many fabrication shops use software tools from Lantek Systems, Inc. (Mason, OH) to maximize the profitability of their design, nesting and sheet metal machining processes for building stoves, washers, dishwashers, ovens or other home appliances. These tools enable them to compile data spanning the entire production process and chart the condition of the appliance being manufactured, labor, materials, machinery and tools. For example, Lantek Wos is a tool that provides control over the entire production process using a system updated with data validated in real time from the factory. This software can be installed on one computer and not only offers options for selecting different machine tools and production facilities, but also allows users to communicate remotely and control machines in the factory to accelerate production processes, making them more effective and streamlined.

Fabricators that design, manufacture, and sell display food cabinets can benefit from the Lantek Manager system, which simplifies and streamlines all production processes, optimizing costs and delivery deadlines as much as possible. This technology shows a factory’s workload and also provides a flexible way to modify the tasks assigned, thus optimizing the use of machine tools, operators and subcontracting centers, among other aspects. One of its main advantages is that users can reserve materials for a specific project or prioritize certain tasks from a single office, thereby reducing product delivery times. Expert Punch software automates CNC punching machine programming and makes it possible to produce modern appliances at competitive prices and with perfect finishes, without sacrificing their design.

Shops that manufacture kitchen appliances and metal home furniture also benefit from Expert Cut software that automates the programming of plasma cutters, oxy-fuel cutting machines, laser cutters, and waterjet cutting machines used in sheet metal and heavy plate operations. This powerful tool prevents unwanted behavior during actual operation. Another tool is Flex3d SW software, which makes the three-dimensional design of any piece easy. It allows users to start from a solid base and add different faces, with an option to change their dimensions until the piece’s design is complete. All of these software tools provide competitive advantages for manufacturers of home appliances and metal furniture, where speed, precision, and technological systems are crucial to profitable production.

Lantek Systems, Inc., Mason Technical Center, 5155 Financial Way, Suite 6, Mason, OH 45040, 877-805-1028, Fax: 513-492-8298, www.lanteksms.com.